Hei bloggen!

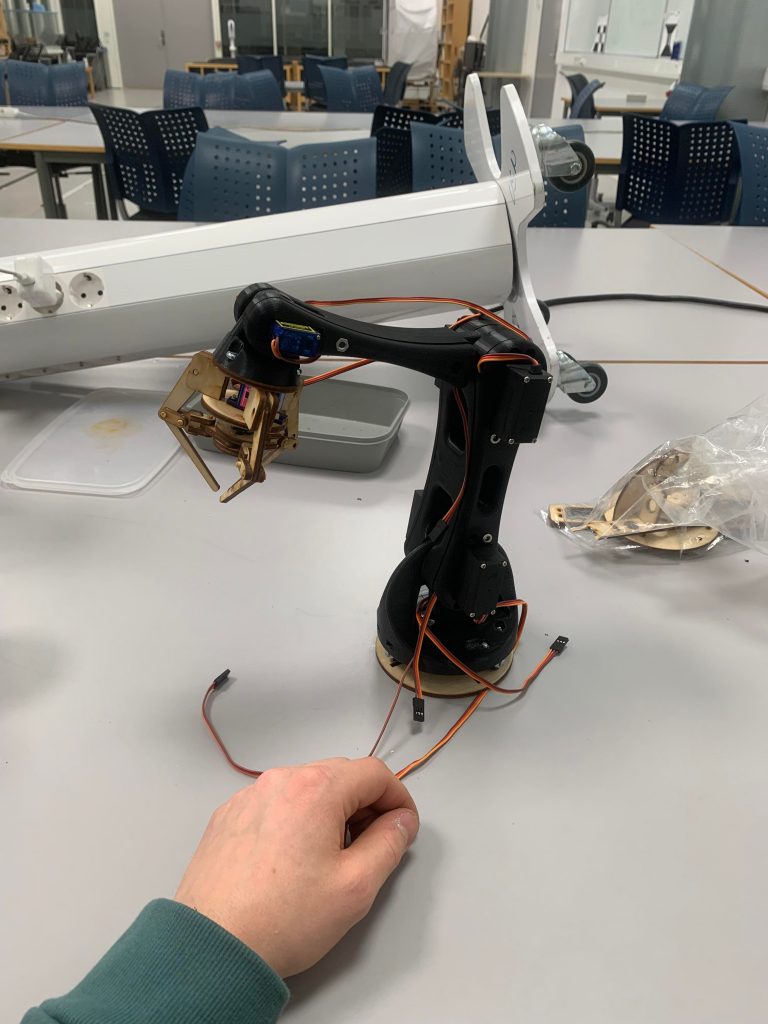

The 3D print of the arm is finished. There is some minor fixes to the arm that Dag is fixing, so when that is finished, we hope there is nothing more we have to do with the hardware. Then we can just focusing on adding some idead we do have to it. We hope we will have to time to finish those ideas. We are experiencing some big problems with power connection. We are using some battery packs with 4 AA batteries inside each of them. This battery packs are not the best and we have had huge problems with these. We have probably soldering the connection to eachother a lot of times because the wires and the connection itself falls of etc.

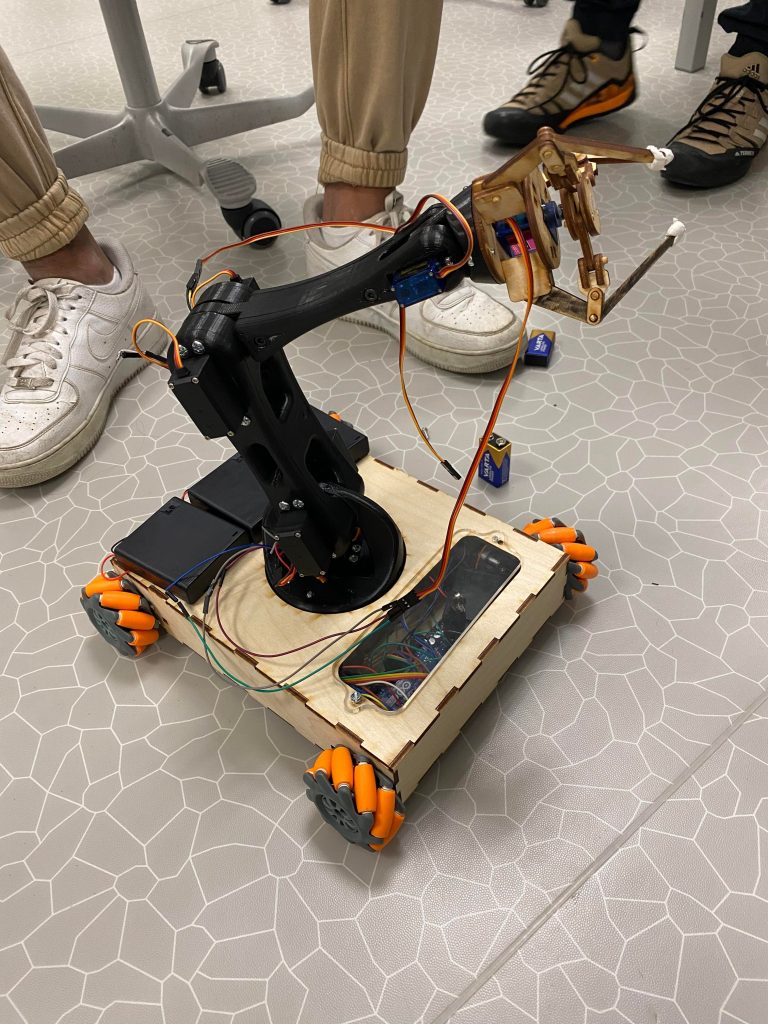

This is the final week of our project before our presentation and the individual talk next week. This project has been a challenging experience, but a fun one. We have learned a lot of eachother, and about making a physical system together. Things has taken a lot longer than we anticipated when first starting this project, but with this said we are happy with our project and what we have been able to make. This unmanned ground vehicle can be used to all sort of different tasks. We wanted to do more with the project, but we to little time we didn’t get to go thorugh with them. We have fulfilled our A and B requirements so we are happy with what we have manage to make this autumn.

Mechanical

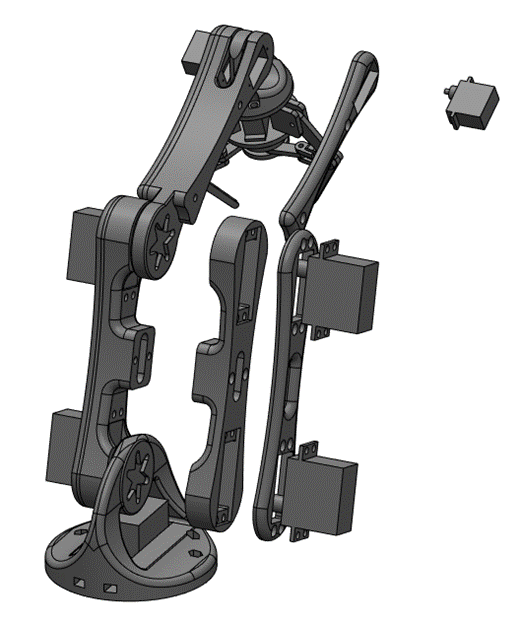

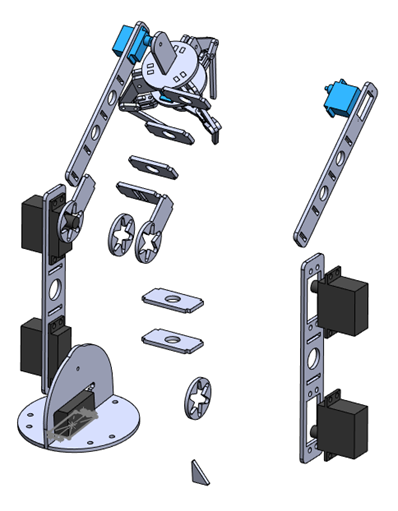

The group wanted to make the arm out of plastic instead of plywood, the main reason for this is looks. But one big advantage is that there are less parts and the ability to hide the wiring.

Modeling 3D-printing

Modelling the arm for 3D-printing was quite fun because there are very little constrictions to what you can make. There are some but not as much as the laser cutter. 3D-Printing is a nice way to make a prototype of a product or a one-off part, but it is not suitable for series production. That’s why I wanted to make the arm out of plywood in the first place. But for a project like this 3D printing is fine.

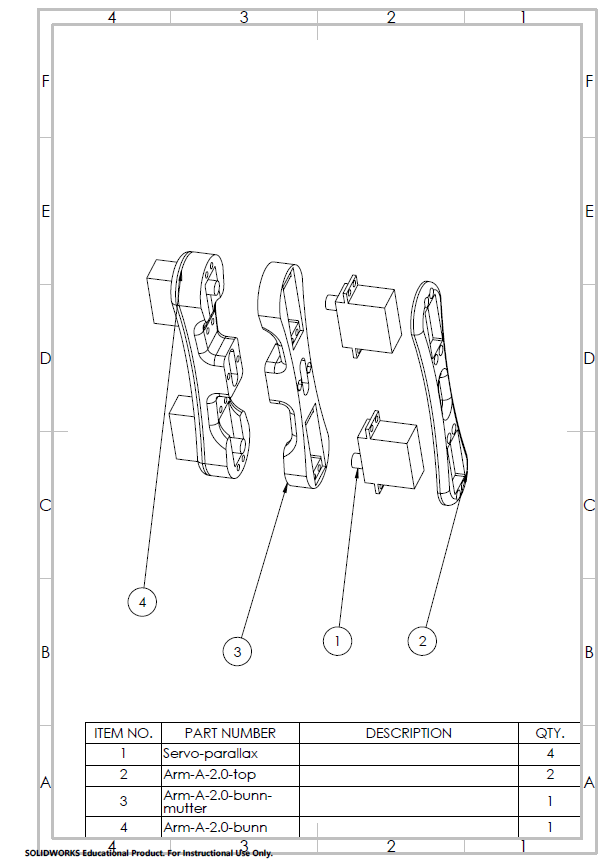

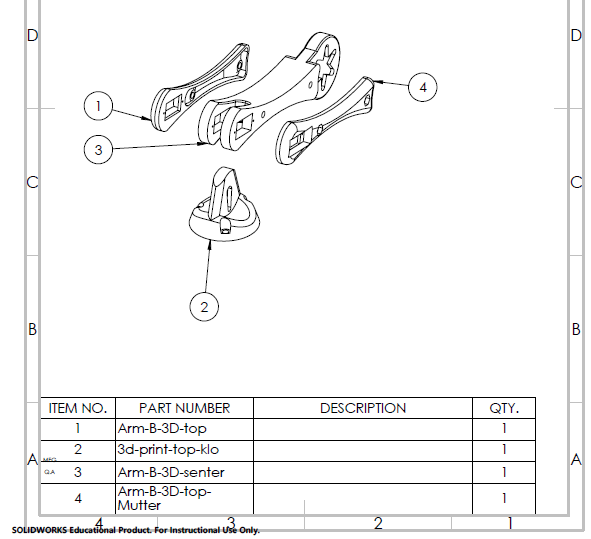

The design of the 3D printed arm.

Alle the work I have put in too the plywood arm made the modelling of the plastic arm easy. Because I could use the basic geometry to model after. Because I know the parts was 3D printed, I made the design as interesting I could but still functional.

To make the arm a bit nicer I decided to hide the cables inside the arm. The way I did this is that I made a hollow cover that went over the engines and cables.

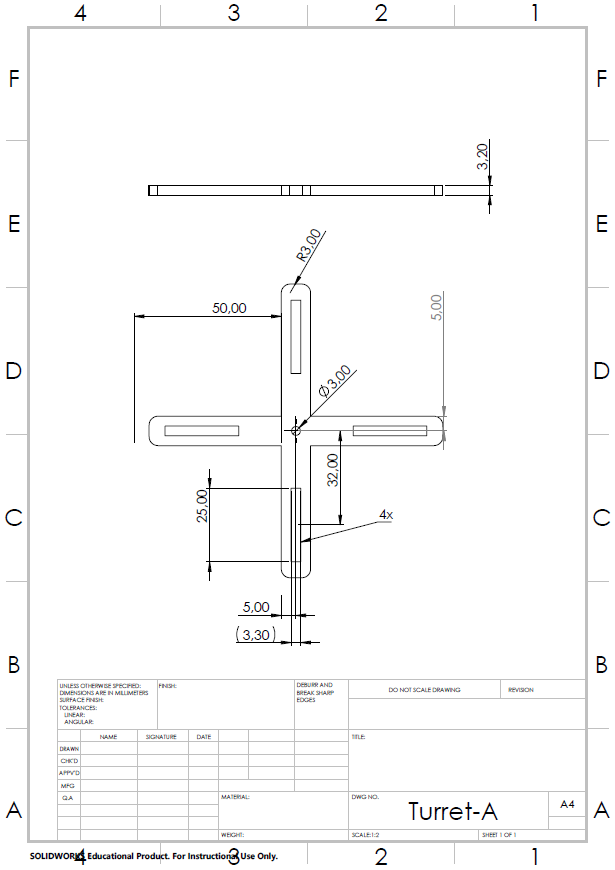

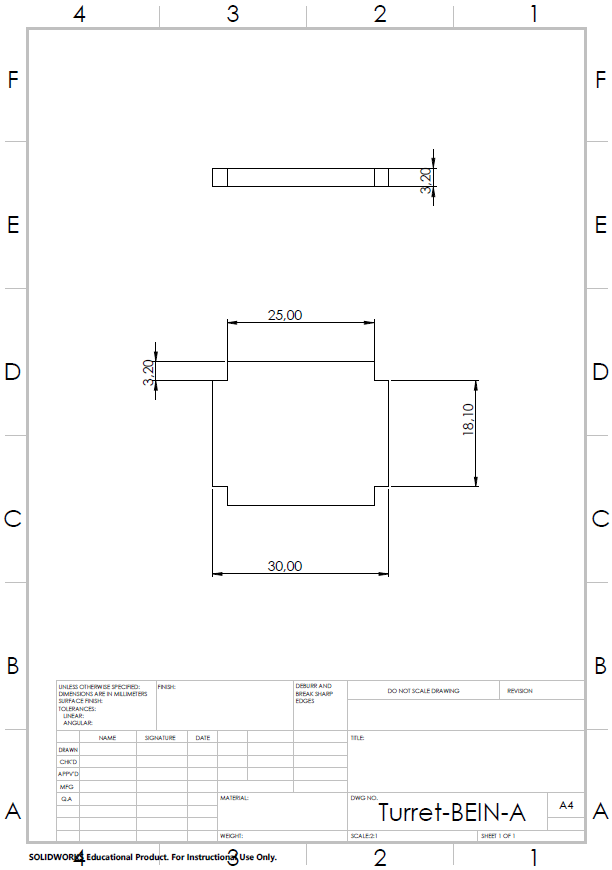

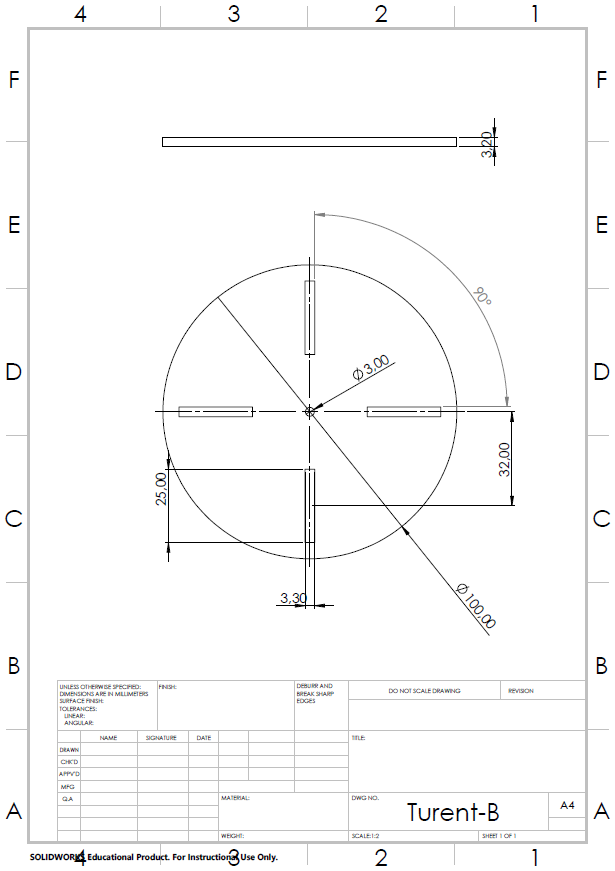

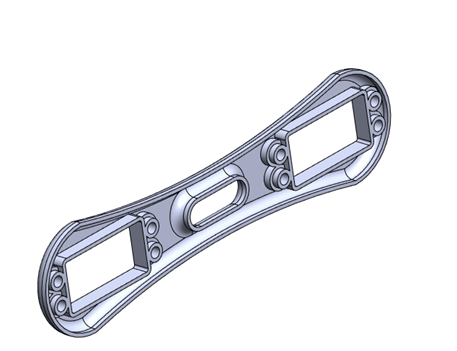

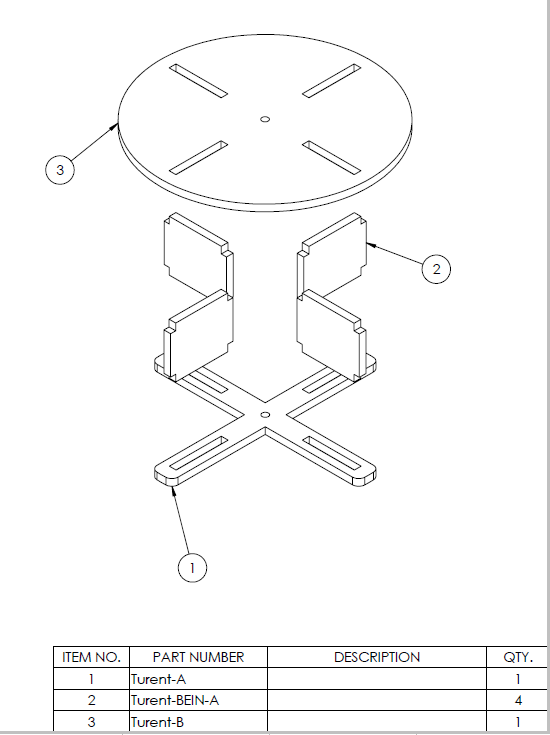

Some 2D drawings of one of the subassemblies, this subassembly is not visible when everything is put to getter. But is has an important part, it connects the Vehicle and the robotic-arm together.