See the video below for a description of our system!

– The Sort.it Team (Thank you Liv-Marte for the group pic)

Mechanical engineers

Optimalizing functions together with computer engineers and Ole. We need the system to function properly before the presentation.

Ole is also adding a web-camera to the sort.it.

See the figures below for an overview of the components of the system

Link to part files and assemblies of the Linear Rail System:

https://www.dropbox.com/s/d9d750k7woviekh/Final%20Iteration.zip?dl=0

Computer Engineers

This week we were finalizing the software, and making sure everything worked as expected. We achieved this by doing the following:

- Stress testing the system too see if it still produced expected results.

- Quality controlling the code.

- Discussing the system to see if we could improve things.

- We read even more about the libraries

Stress testing

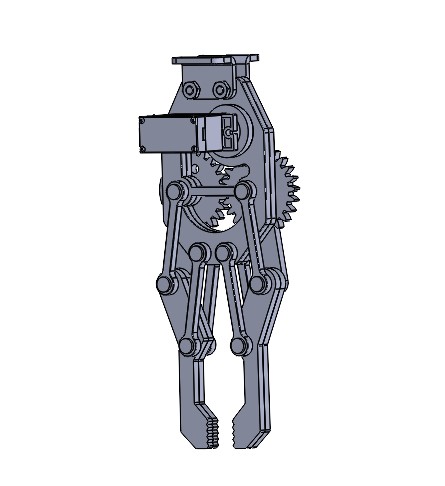

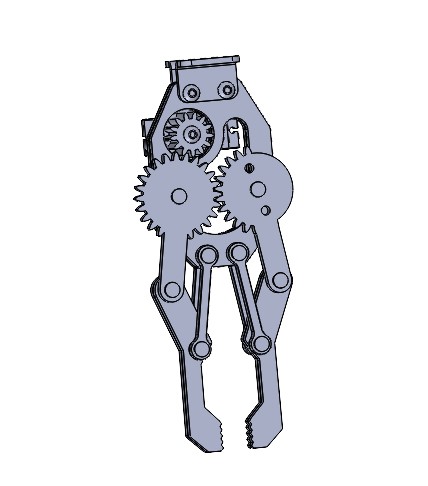

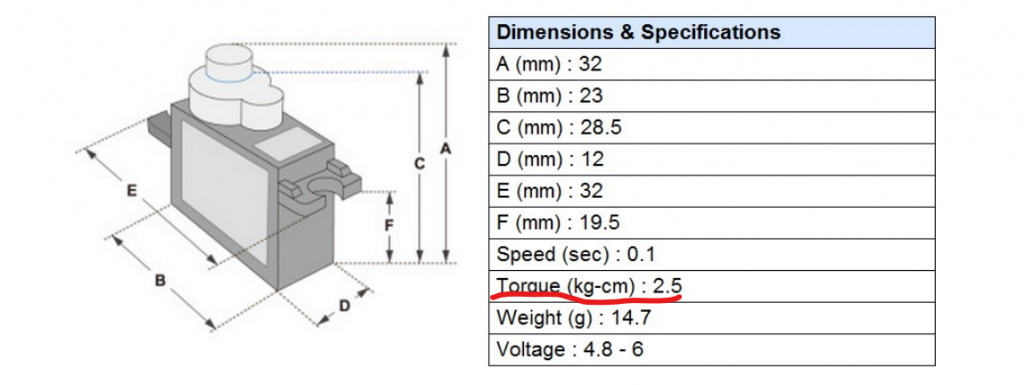

Since we wanted the system to work for the presentation day we decided to stress test the system and it turned out to be a bad idea since there were some vibration causing the screws in the claw fall out. So if we tighten up the screws really hard then the servo motor we used was not as strong. On the datasheet it is written that the torque power is 2,5 kg in the center and weaker the farther from the center. So therefore we started to check with our hands how much power we needed to open the claw when the screws were tighten really hard and it required alot of power atleast more than 2,5 kg and since the power applied was not in the center we knew we had to losen up the screws.

Quality controlling the code

At this point we(computer engineers) sat down together and looked at the code and tried to look for improvements. We saw that our commenting was not on point so we decided that is where we all should focus. In order to this we had to comment several important factors of the library that we knew but what should inform clearly on the code so that any computer engineer can do the same.

Electronics

This week I soldered wires onto two end-stop switches in case the computer engineers decide they want to use them. I have also replaced some wires on the drivers to make it look tidier. Also, the wires from the Arduino kit are not that suitable for connecting to the components, besides the Arduino. The computer engineers wanted to test the RFID reader, but I had connected some of the wires wrong so I had to fix that.

After this week I am all done with the wiring and cable management as we won’t be using the end-stop switches, after all, so now we are just waiting for the computer engineers to finish the coding, and hope nothing breaks during testing until we present our system.

Sadly, some wires on the drivers got loose and this made the stepper motor for the x-axis go in one direction, and the wrong direction. There was also one wire I didn’t see for a while that got loose, and luckily that was the source of the whole problem.

– Mathias

Major Contributions

Ole Markus Lie, Mechanical Engineer

- Design of linear rail system

- X, Y & Z – axis mechanics

- Assembly

- Cable management

- Summary video

Kim A.R.Gudbrandsen, Mechanical Engineer

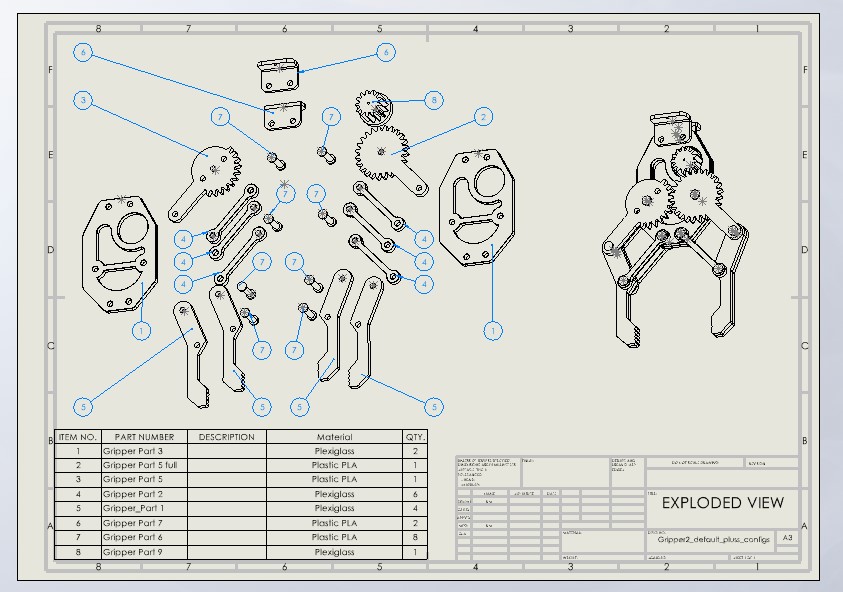

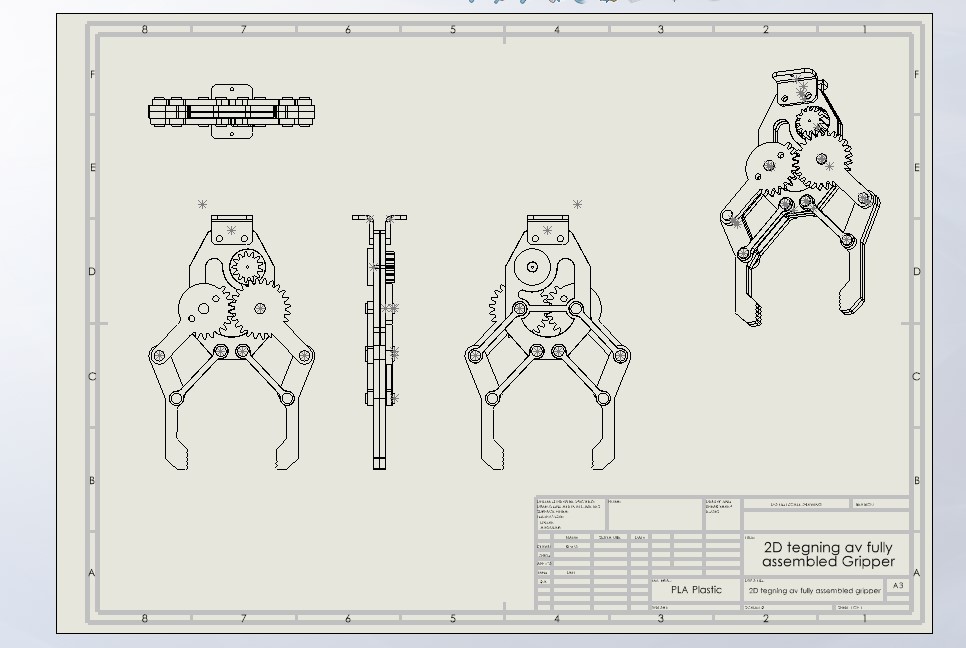

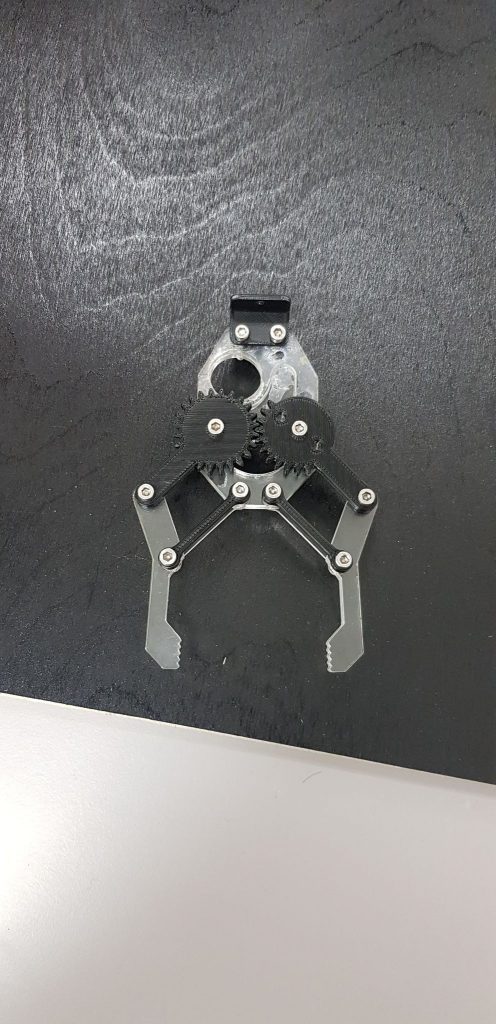

- Design of gripping claw

- Production & manufacturing

- Assembly

Samuel Said, Computer Science Engineering

- Linear rail system control

- User interface (UI)

- HTML & CSS

- Electrical – Initial Pin Setup

Martin Kopland, Computer Science Engineering

- Linear rail system control

- User interface (UI)

- RFID scanner

- HTML & CSS

- Electrical – Initial Pin Setup

Jim Christian Haukvik, Computer Science Engineering

- Integration of Raspberry Pi & Arduino

- Linear rail system control

- UI

- HTML & CSS

- Electrical – Initial pin setup

Mathias Sandvold, Electrical Engineering

- Final pin setup

- Cable management

- Component management