Computer engineers

This week we tried to focus fully on setting up our user interface on raspberry pi with the touch screen. We decided to use electron for setting up our desktop app. For this we had to use JavaScript, HTML and CSS along with some scripting. There were several issues when we tried to setup electron on the raspberry pi. We had some issues with downloading the app but in the end we found how to download it but then we had problems with setting up the scripts for it to run. We managed to fix that problem as well.

Mechanical engineers – Production

Since computer engineers wanted to have a touch screen working with the sorting system me (Kim) and Ole made a simple display case for the touch screen. Made it in plywood as you can see below.

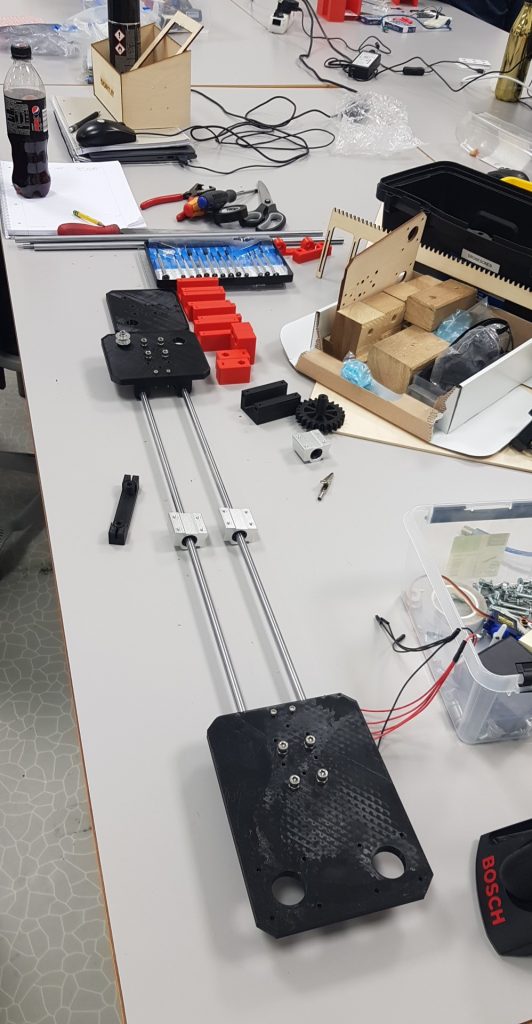

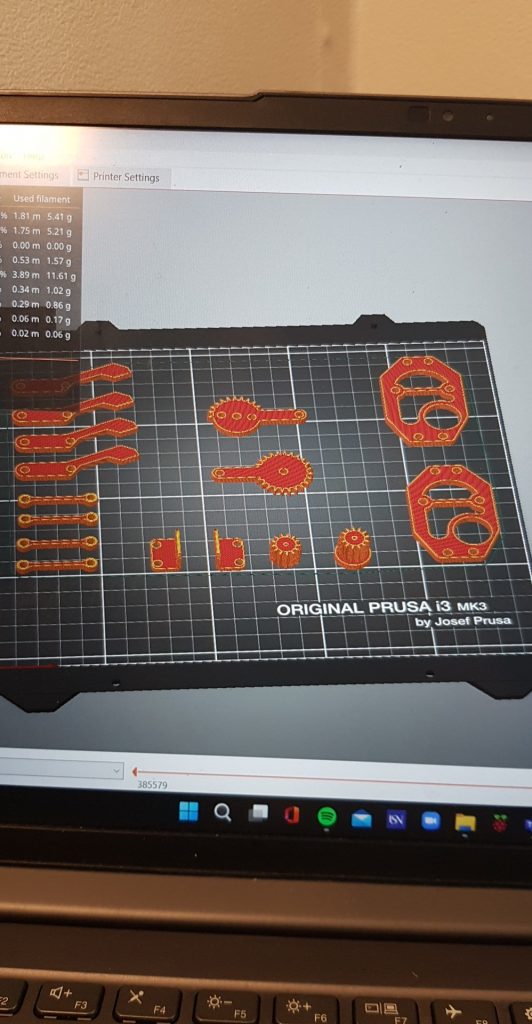

Down below you can see the rail system in the beginning of being mounted. First in plywood to see if it will work and now this will be replaced with only 3D modelled parts for more rigidity.

We are still missing some 3D modelled parts, but these are on the way and will be connected as soon as possible.

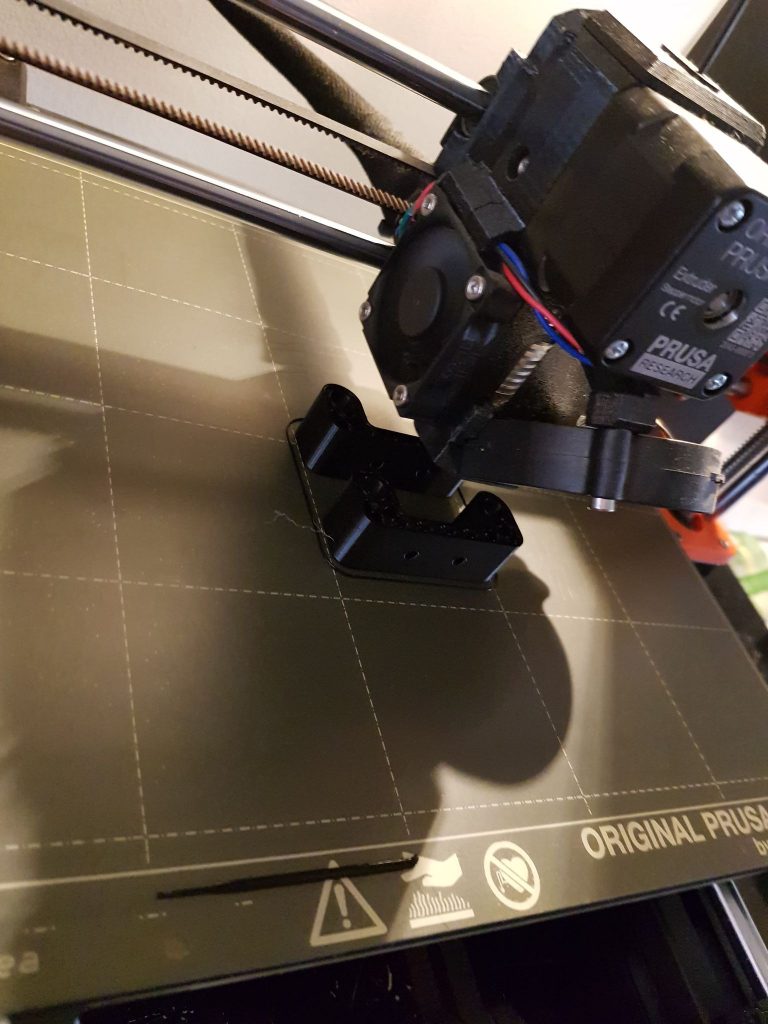

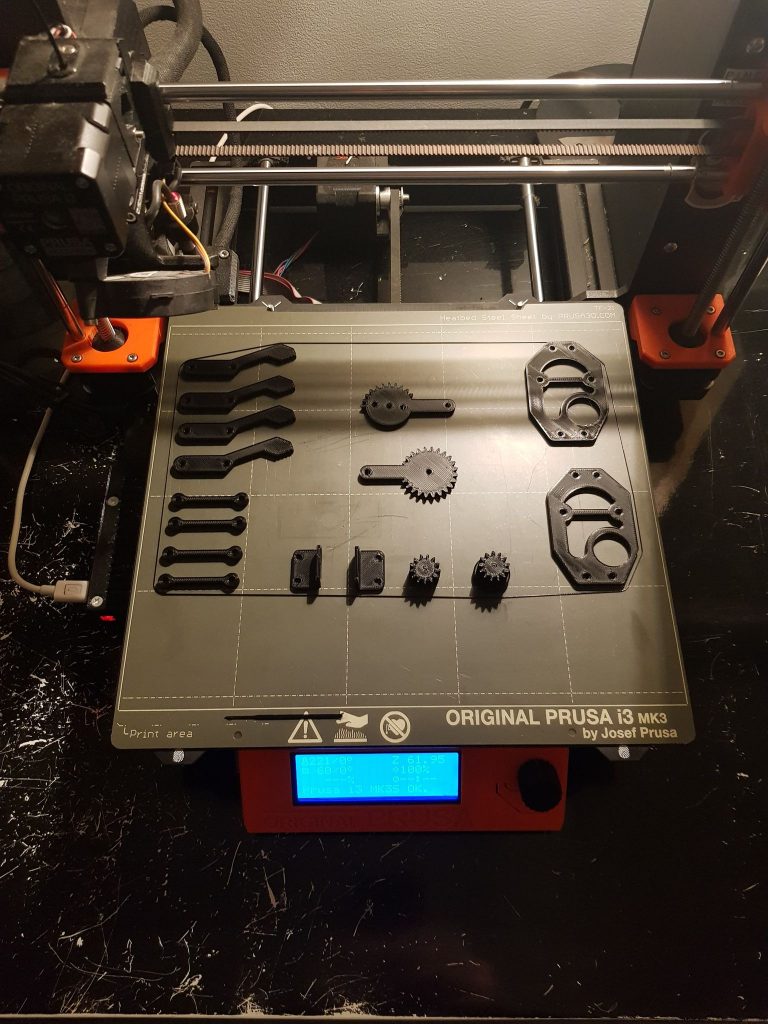

Since we didnt have all the 3D parts, and I had the possibility to print on my own at home, Ole Markus sendt me the STL files and I printed the remaining of the 3D models he had made in SW. It was a good amount of parts, so total print time was around 20hours. I also took the liberty of adding a engraved logo on one of the parts Ole Markus sent me.

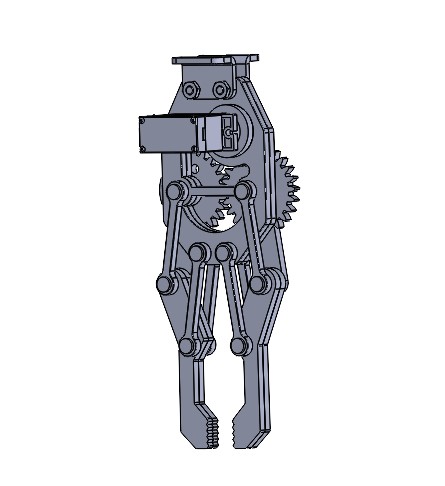

I also printed the new gripper/claw in 3D printed parts. This weekend the printer was going non stop. Almost 30hours.

– Kim & Ole Markus

Electronics

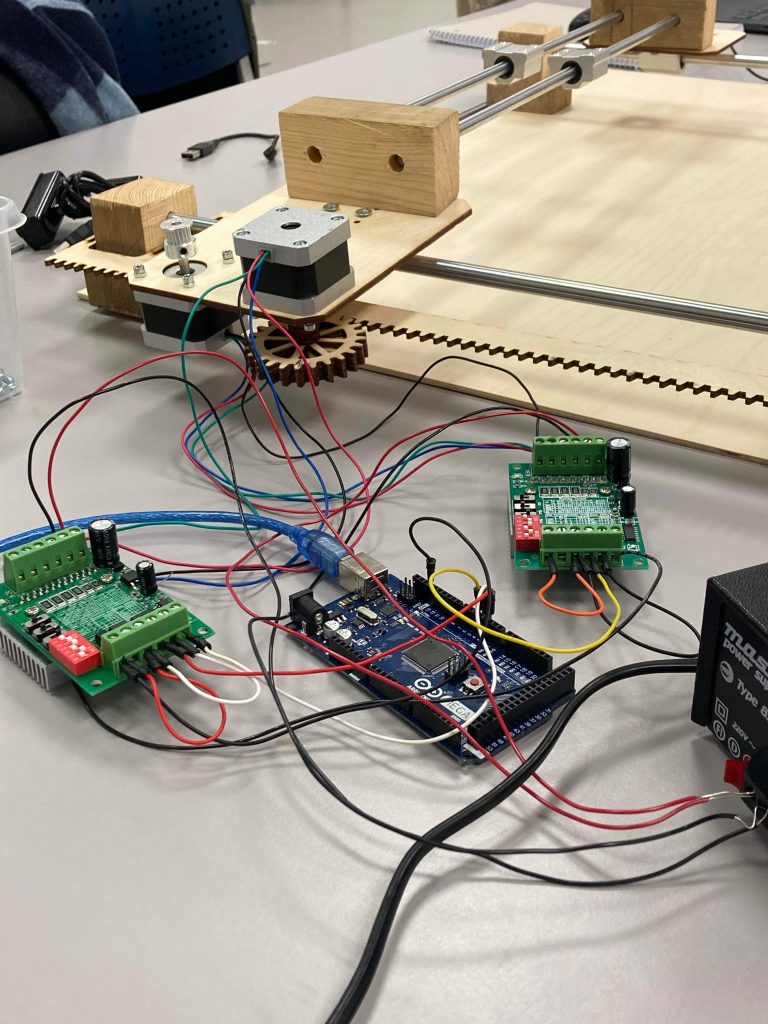

For the past few weeks, I haven’t had much to do besides waiting for the prototype of the system to be ready for me to wire up and start testing everything together. For now, I won’t be doing much cable management as we will be taking everything apart as soon as the final build of the system is ready, therefore the wiring is quite the mess for now. Therefore, I started drawing a wiring diagram for our system.

The computer engineers wondered if it would be possible to use one stepper motor driver for two stepper motors to save space and maybe make the coding simpler, and it is. However, then we won’t be able to control the two motors separately because there is only a set of signal inputs on the drivers.

The voltage drop we found on the servos a few weeks back ended up not being a problem after all. Especially since we will only be using one servo instead of two.

– Mathias