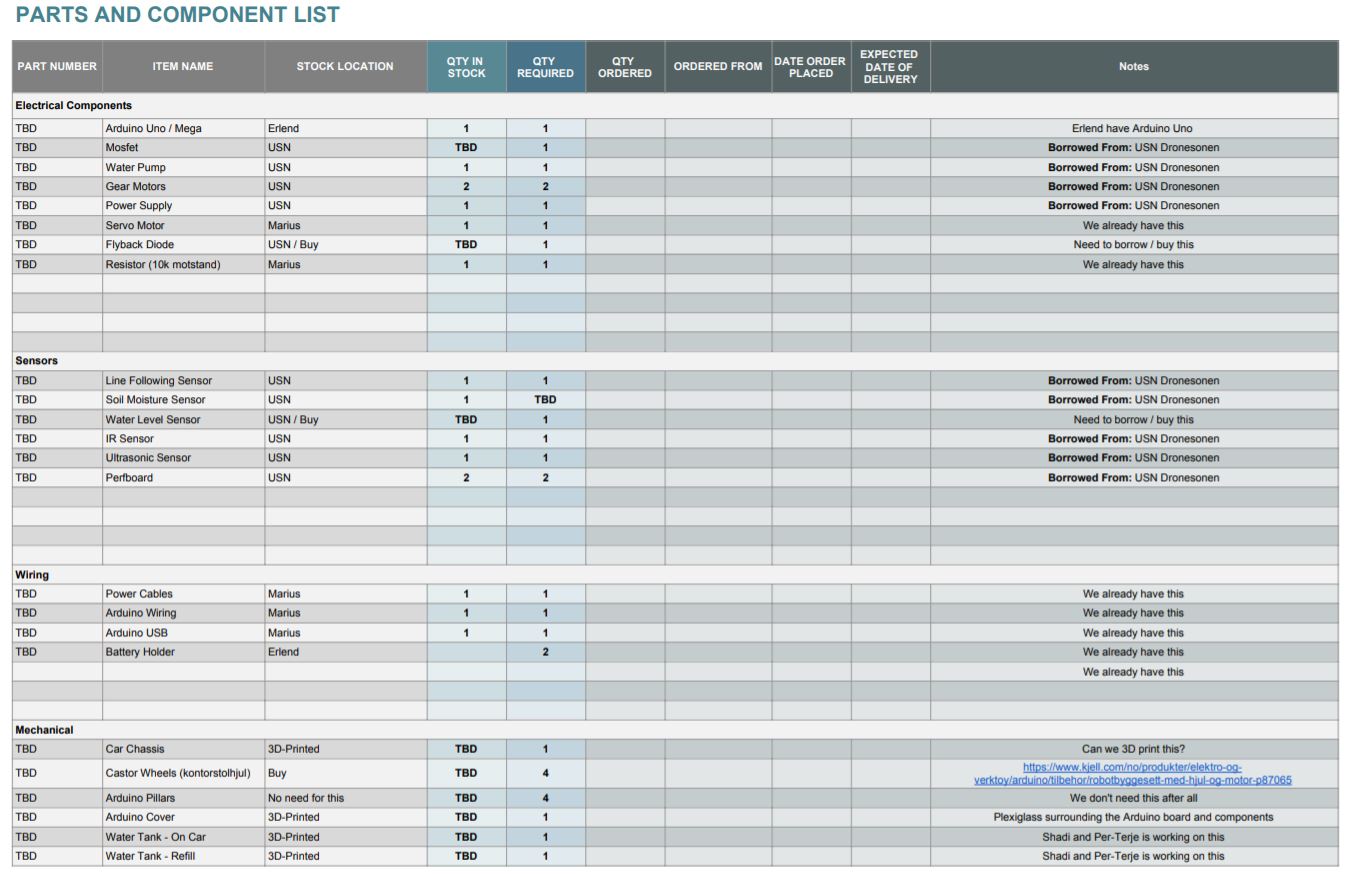

During the past week we have focused on creating a parts and component list for our system as well as trying to get hold of all the necessary parts. After working on this on thursday we managed to get most of the parts we needed.

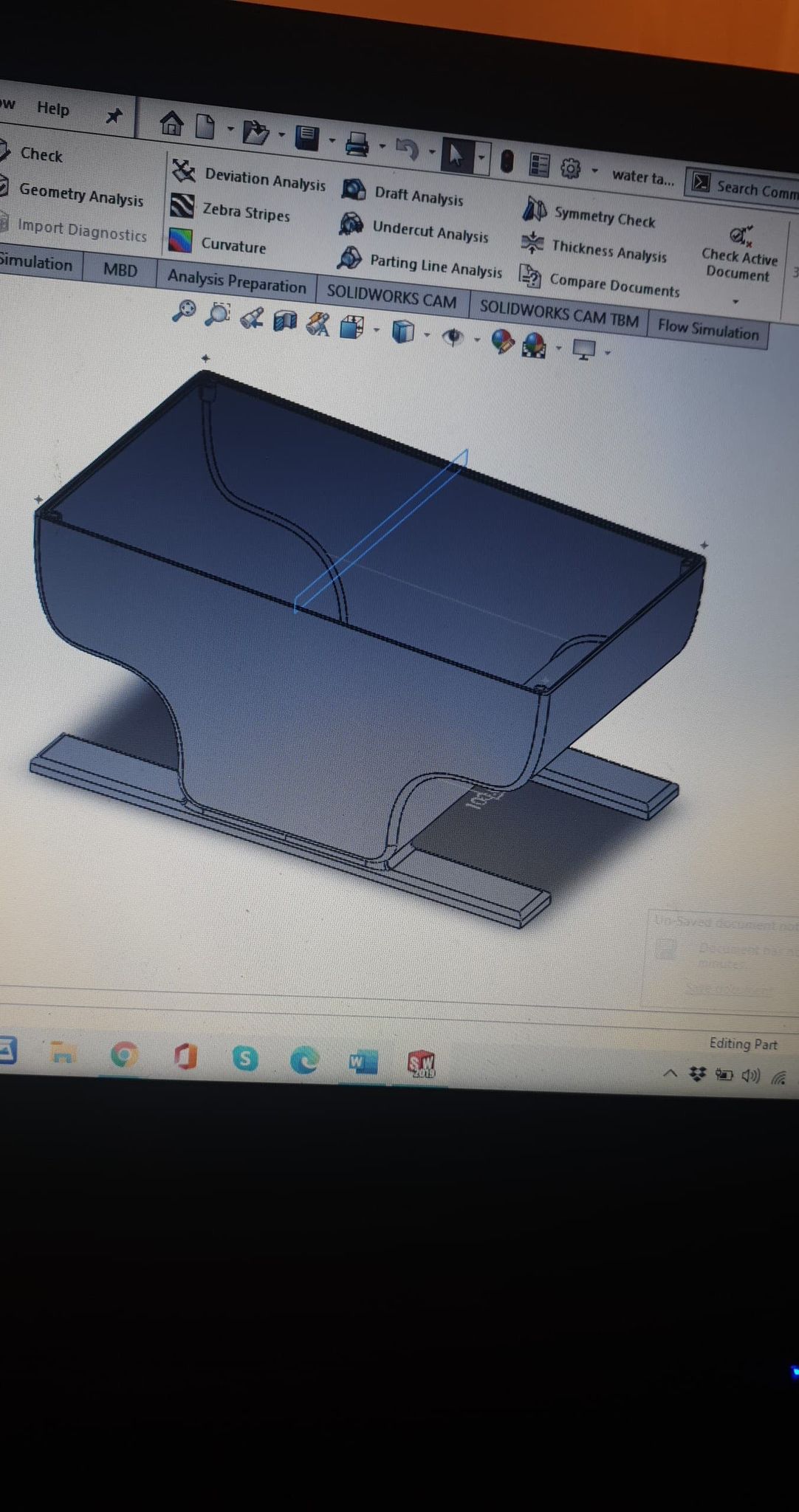

We have also started working on the 3D design of the car chassis, wheels and water tank as well as other parts that are going to be 3D printed. Hopefully, this will be done and 3D-printed during week 38 so we can start moving onwards with the assembly of the system components. While waiting for the mechanical aspects to get finished, electrical engineer (Erlend) and computer engineer (Marius) are working together testing the various types of components to see if it matches our requirements regarding power, weight etc.

Parts and component list of our system:

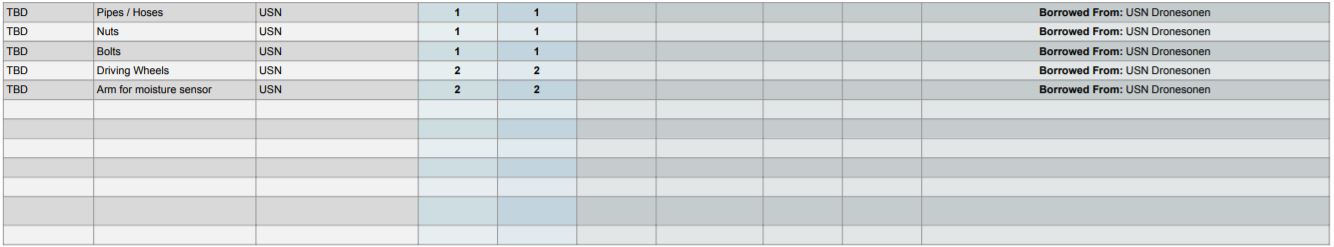

We have obtained most of the parts and components we need for the project, but some of the components will have to be determinated as we go along. The parts and components list provided beneath show most of the parts needed for our system.

SolidWorks:

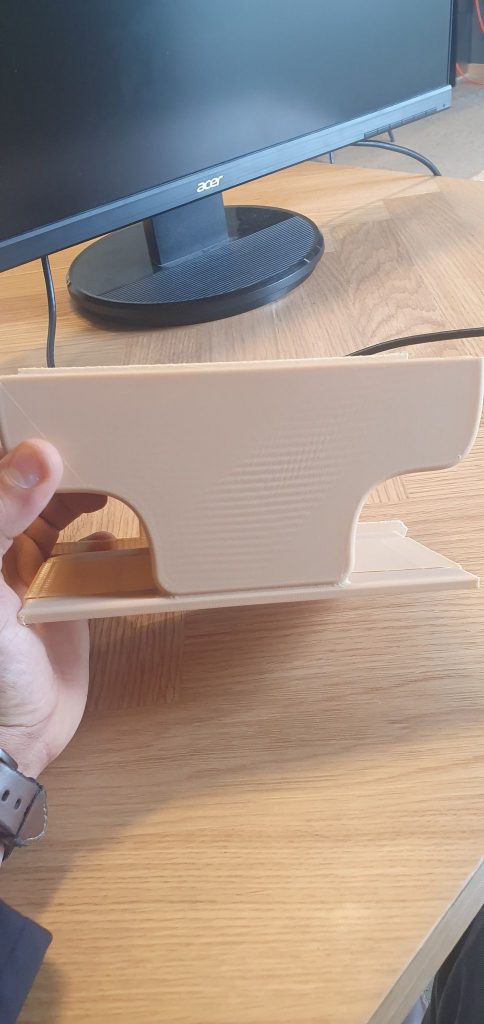

Our mechanical engineers (Shadi and Per-Terje) have started working on some of the parts for our watering system. During this week they have created the models for our water tank that will be attached to the vehicle, and have started to 3D print the parts that can be seen on some of the images and videos.

Electrical (Erlend):

Did some research and testing of the functionality of the different line following sensors that we gathered from dronesonen to see if they could be used for our project. Concluded that the IR-sensor which I had envisioned from the start would best fit our project.

(An IR-sensor measures and detects infrared radiation in its surrounding environment. The sensor both emit and detect infrared radiation). Ordered two IR-sensors alongside a soil moisture sensor and an LM393 comparator to use with the soil moisture sensor we already had.

Update 14/09:

At the end of last week (week 3 of the project), some of our main mechanical components were 3D printed and finalized. The water tank which will be able to contain 1 litre of water can be seen on the image beneath. The idea behind the design of the water tank is that some of our components can be mounted on the sides of the curves on the tank.

Shadi has also 3D printed the mounts for the gear motors so they easily can be attached to the body of the vehicle.

Our plan for week 4 of the project is to move onwards with the assembly of the different parts and components, as well as starting on the programming part of the project.