28.10.2024 – 03.11.2024

“And the haters gonna hate, hate, hate, hate, hate.”

-Taylor Swift

Group Summary

Dearly beloved,

in these later stages of the development the computer engineers are really starting to showcase their excellence in crafting software and algorithms. Fredrik and Robin are working tirelessly on the GUI that the players will interact with, to observe points, time left etc.. While Eirik has been working combining computer vision code with servo controls for the shoot-back system. Vetle is waiting for his PCBs to arrive in the mail. Kadir has done some brilliant work in 3D models for the shoot-back unit. While Hans is stuck in the middle of the sea.

Individual Summaries

Eirik (Data):

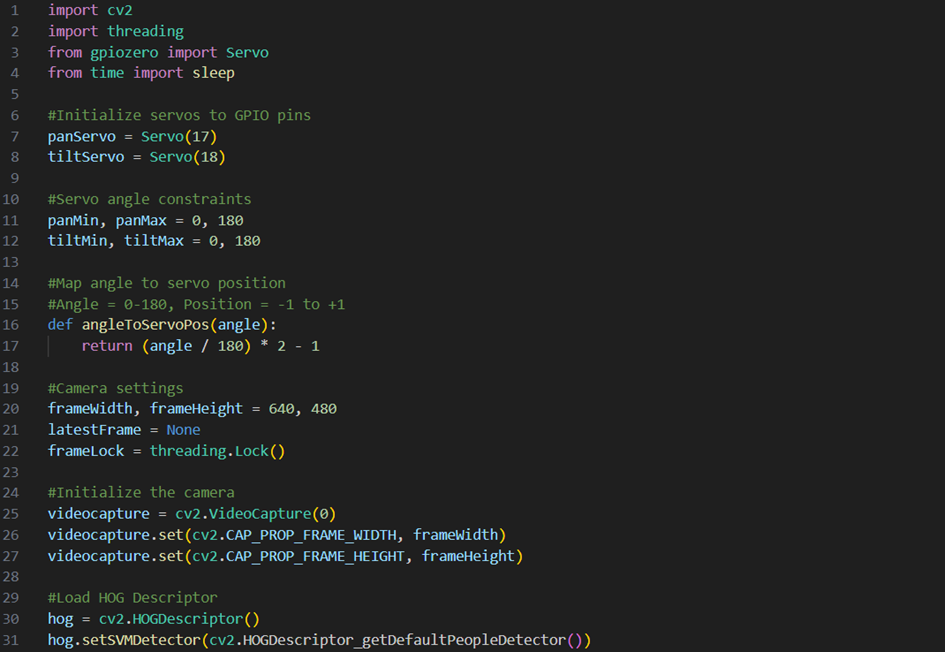

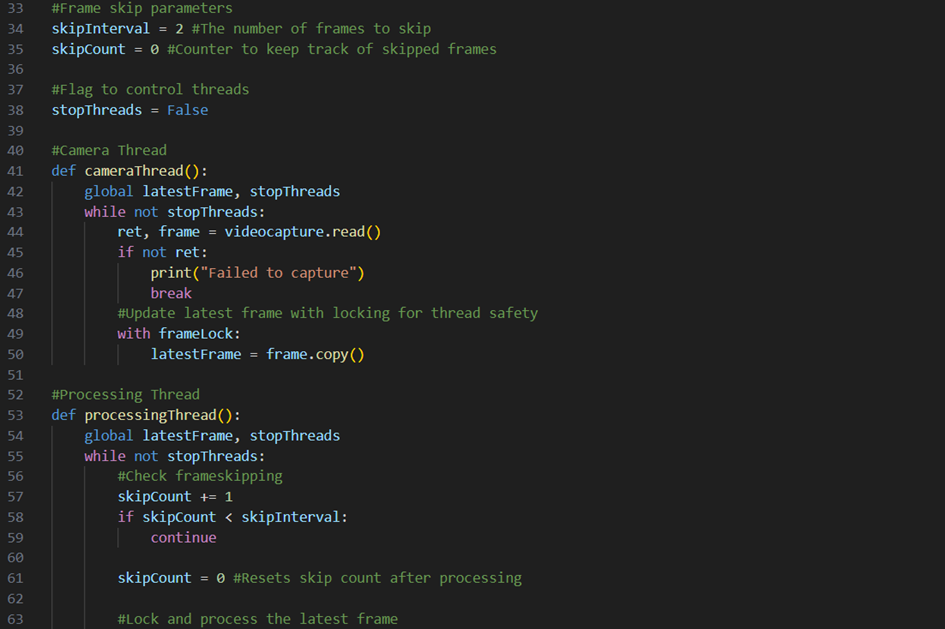

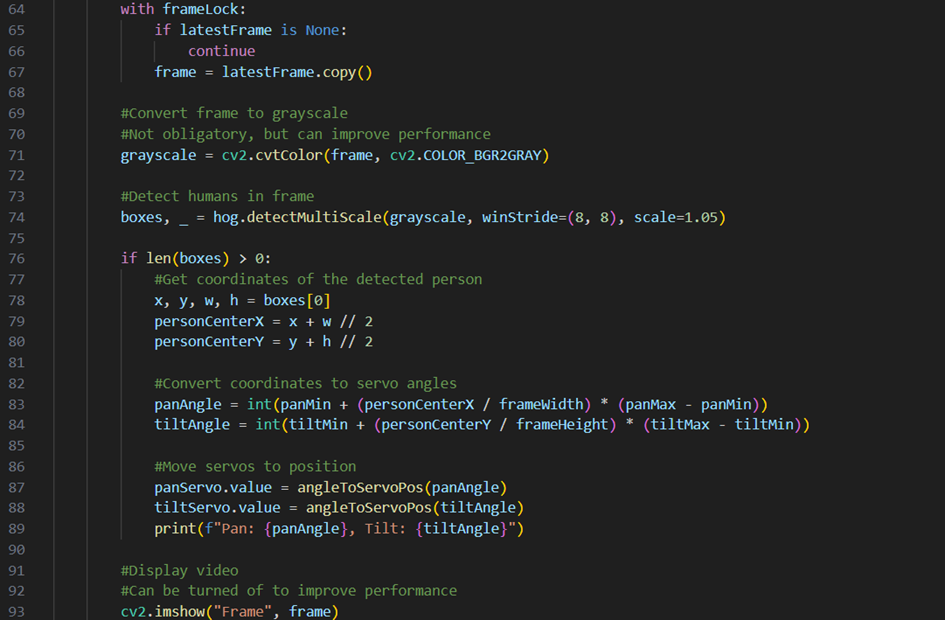

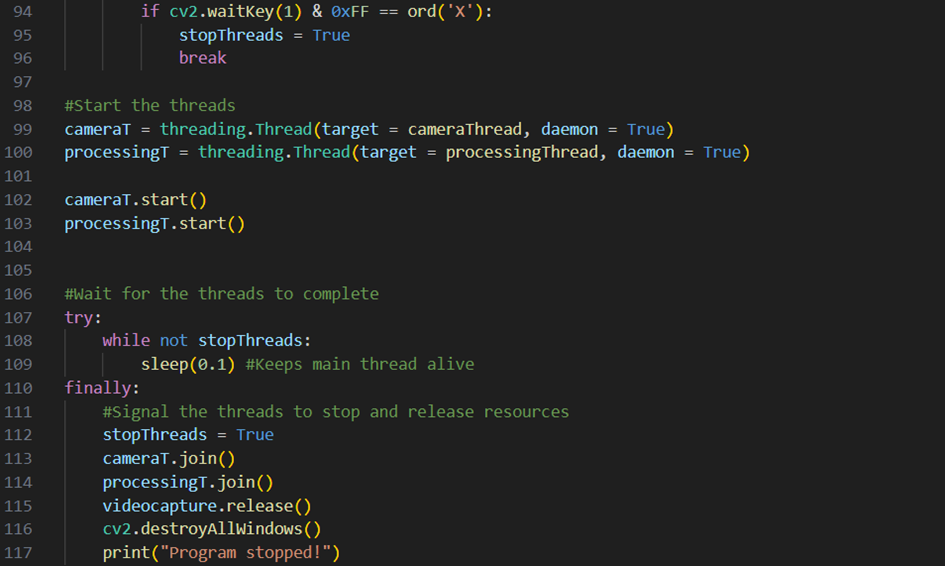

This week I have been working on code for the shoot-back system. The process has been to implement servo controls with a Raspberry Pi through the already existing computer vision code, the idea is to get the servos to move autonomously based on what the camera sees. This is done by converting the frame into a coordinate system and giving information to the servos about where in this system a human has been detected, so that they can move based on this.

This is how the code looks like, yet I have no idea if it actually works as of now (Sunday, November 3rd). Hopefully I can test it with servos and the Raspberry within the next few days, so maybe on the next blogpost I can write about how brilliantly (or horribly) it turned out to perform.

Another thing I would like to try, and implement is to make the computer vision part solely lock on to a single individual. This can be a useful feature to have since there are most likely going to be other people around when the project is being used, and this would eliminate the risk of the shoot-back system trying to aim at anybody else than the person who is participating. This can possibly also eliminate the risk of the code also marking random objects as humans for a split second every once in a while, hopefully.

Robin (Data):

This week has mostly been about preparing for the PCB to arrive so we can actually test our system when it arrives. In that regards my work have been to start integrating the systems developed on to the raspberry PI. I have implemented a little new code this week but have instead been a bit stuck with errors in my effort of integrating the different systems. So, I have to continue my effort to better understand python and how to correctly integrate everything.

Fredrik (Data):

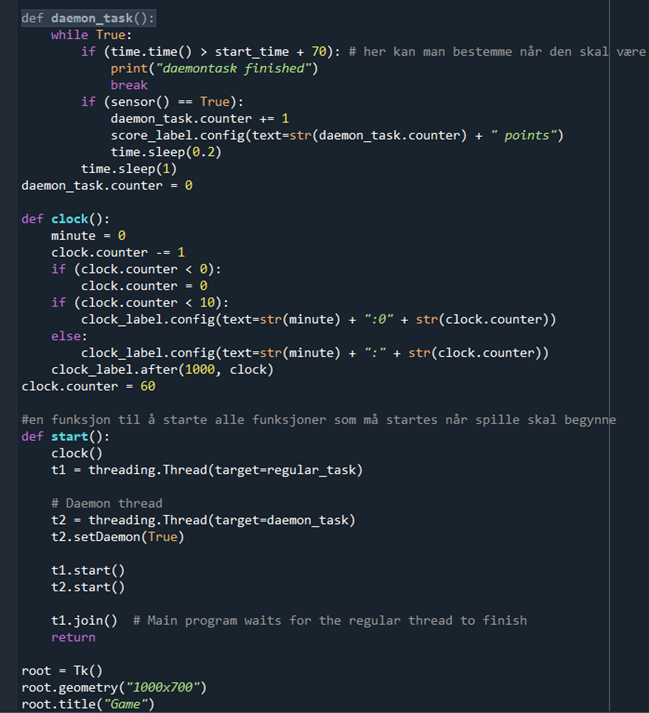

This week I worked on making the timer that goes on the GUI. Where I tried to use time.time() but ran into the issue that it could not reset the start_time variable, so I switched over to a function counter instead which worked better. I also tried to implement the point system into the HUD, which was a bit of a struggle at first, but I got it working after a while.

At the same time, I tried implementing the start button, timer and point system into the existing code for the system which somewhat worked. After you press the start button, the GUI screen freezes for 3-4 seconds while the movement code goes and then the timer and point counter comes, and this is not supposed to happen. As for the looks of the GUI I haven’t done anything yet, but I have looked at how you do it.

Vetle (Electrical):

I have not been doing a lot this week since I am waiting for the PCBs and stencil to arrive from China. The PCBs are scheduled to arrive by November 6.

Kadir (Mechanical):

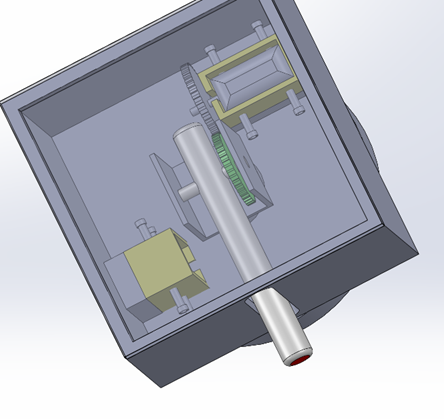

This week, I worked on adjusting the dimensions of the gears to ensure they fit correctly in the assembly. I modified the box to align precisely with the gear and made sure that the gear from the motor rotates the laser holder. I also spent time trying to use gears from the toolbox, but since they did not work as expected, I had to create new parts from scratch. Now, all the components work together as they should, and the entire construction is more stable. Moving forward, I will fine-tune the assemblies to ensure optimal performance in the system.

Hans (Mechanical):

This week I have been working remotely due to offshore rotation,

I have spent time learning more about FEM analysis, in the terms of Contact simulations, and vibrations.

Planning for rebuilding the base frame to a nicer finish when I get back home.

Have decided to put on some wires and ‘’Adjusters’’ on the bardunes to enhance stiffness and look.