In this week we have focused on finishing most of undone tasks.

Benjamin:

This week was a little bit of a set-back for me, as I redecided and redesigned our webpage. After looking at some of my example sights over again I figured out that format needed to be changed. So Ive adjusted sizes for buttons en text areas, changed the colour schemes and changed the buttons. Ive also started looking at different domain sites, so our webpage can get its own domain.

Azi:

Log: Stepping in for Elevator System

Context:

Kim was to code the elevator system for the smart parking in our group project. He got the motor and buttons up running before he got sick and contacted us thereafter to inform us he would be unavailable for at least two weeks. At that point, the sliding motors for parking slots and sensor integration were still incomplete. In the first week after Kim’s absence, we struggled to make progress, particularly with getting the motor to function properly. To overcome this, I prepared thoroughly for the next meeting by researching solutions and troubleshooting Kim’s code at home. I was more focused on getting main elements-motor, button, and sensors operating rather than moving on to advanced features such as a sliding mechanism.

Actions Taken:

• Came with previously done work to stabilize the elevator’s motor and buttons:

• My first priority, having prepared at home, was debugging and refining controls related to the motor and buttons in the elevator.

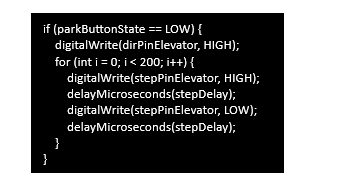

Original Code:

Code Changes I Made:

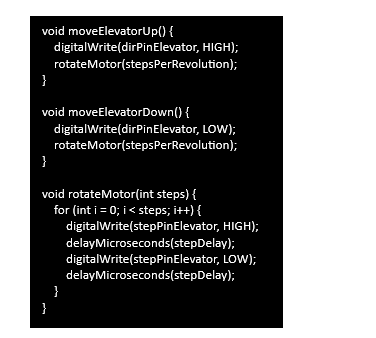

• I rewrote the movement management logic of the motors; I split the code into two functions for up and down movements, with better control of the movement which now operate smoothly.

• This modification made sure that the elevator was traveling consistently between floors and responding appropriately to the input of buttons.

Integrated Basic Sensor Functionality:

• After having stabilized the placing of the motor and buttons, the next integration was a basic sensor system.

• Added a sensor for monitoring the movement and position of the elevator relative to the parking levels.

• This feedback is necessary for the future phases of the project if we have to add more functionality.

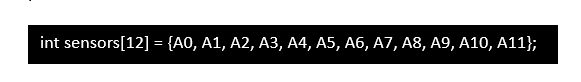

Original Code:

In the original code there were places for having several sensors, but the tracking function of the elevator position was not implemented.

Code Changes I made:

• I simplified the sensor system to include only one sensor, used for tracking purposes to trace the position of the elevator.

• That gave a working feedback loop for the elevator’s current position, which laid the ground for future additions.

- Postpone Sliding Motors to Future Phases:

• Although Kim had planned to include sliding motors for moving cars to left and right parking slots, I decided to postpone this feature.

• Sliding motors were not mounted yet; this would have added complexity at a time when it was not needed.

• Postponing the sliding motors freed the intricacy and helped me emphasize the core functionality in the stability of the elevator system.

• This approach helped me in completing the required tasks, and any advanced features integrated into a motor, buttons, or sensors were guaranteed a perfect working condition. - Completed Thorough Testing and Debugging:

• Once we had the motor, buttons, and a sensor, I did multiple rounds of testing to make sure everything worked well.

• The elevator motor now operates reliably, and the buttons for the elevator function properly.

• In this way, these various tests allowed me to test the stability of the performance of the system across changing conditions.

• The system is now stable and will be used during the next phases as a platform for further development, such as sliding motors and extra sensors.

Outcome:

In the absence of Kim, I was able to stabilize the elevator system, including its motor, buttons, and sensor controls. I also postponed the sliding motor system to a later phase so as to make the present setup less complicated. That, in a sense, allowed me just to focus on the core thing and make sure everything was right in the system. We are now ready to move forward and integrate advanced features when the time comes.

Milani:

This week, I focused on designing the user interface (UI) for the screen that will be used in our parking system. Once the UI design was completed, I worked on connecting it to the database. This connection will ensure that the screen dynamically displays the correct data, such as available parking spaces, and updates based on the information stored in the database. After setting up the database connection, I ran several tests to confirm that the UI is properly retrieving and displaying data in real-time. The tests were successful, and the screen is now ready

What I Did This Week:

- Designed the screen UI for the parking system.

- Connected the screen to the database to display dynamic information.

- Tested the connection to ensure data is retrieved and displayed correctly.

Meron:

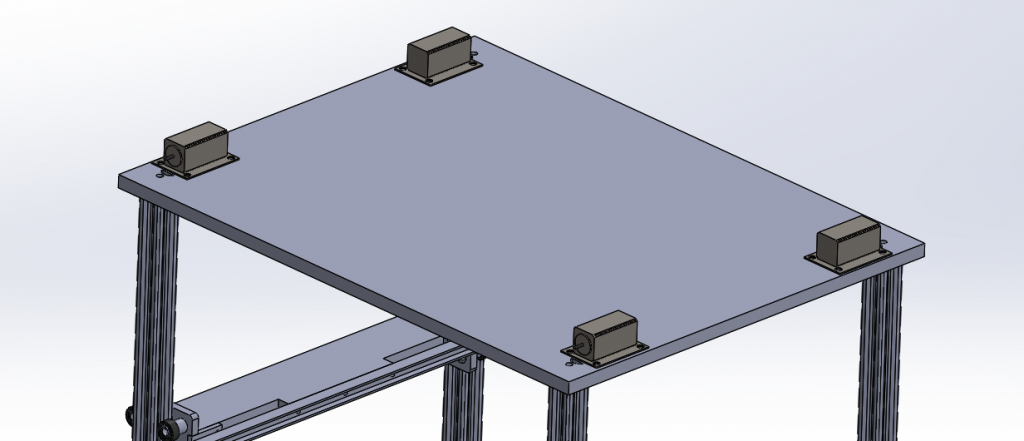

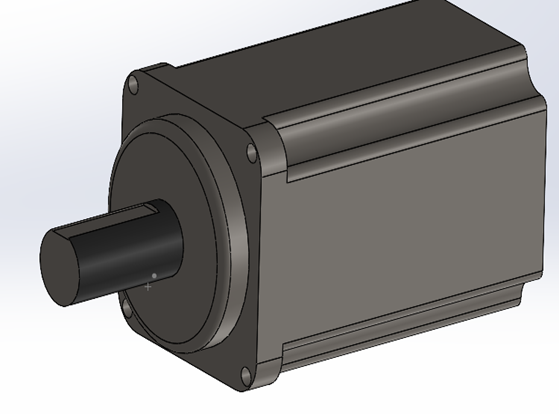

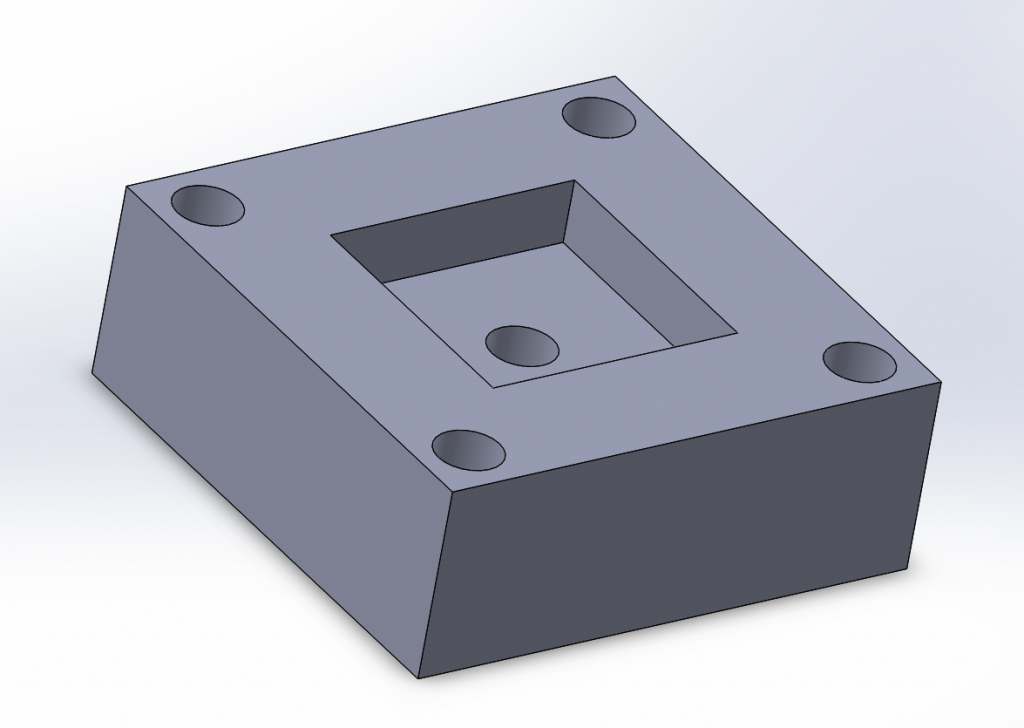

This week, I have focused on developing several key components for my smart parking system. After completing the drawing of the parking levels, I have now moved on to designing the motor and the payment machine using SolidWorks.

The motor is a critical part of the system, as it will drive the mechanical movements necessary to transport cars to available spaces in the parking facility. It has been a challenging yet rewarding process to ensure that the motor is optimized in terms of both space utilization and functionality. By simulating movements in SolidWorks, I have been able to test various scenarios to find the best solution for efficient operation.

Additionally, I have worked on developing the payment machine, which will be a central part of the user experience. The machine is designed to be user-friendly while seamlessly integrating with the rest of the system. I have focused on creating an intuitive user interface so that drivers can easily pay for parking without delays.

Shanel:

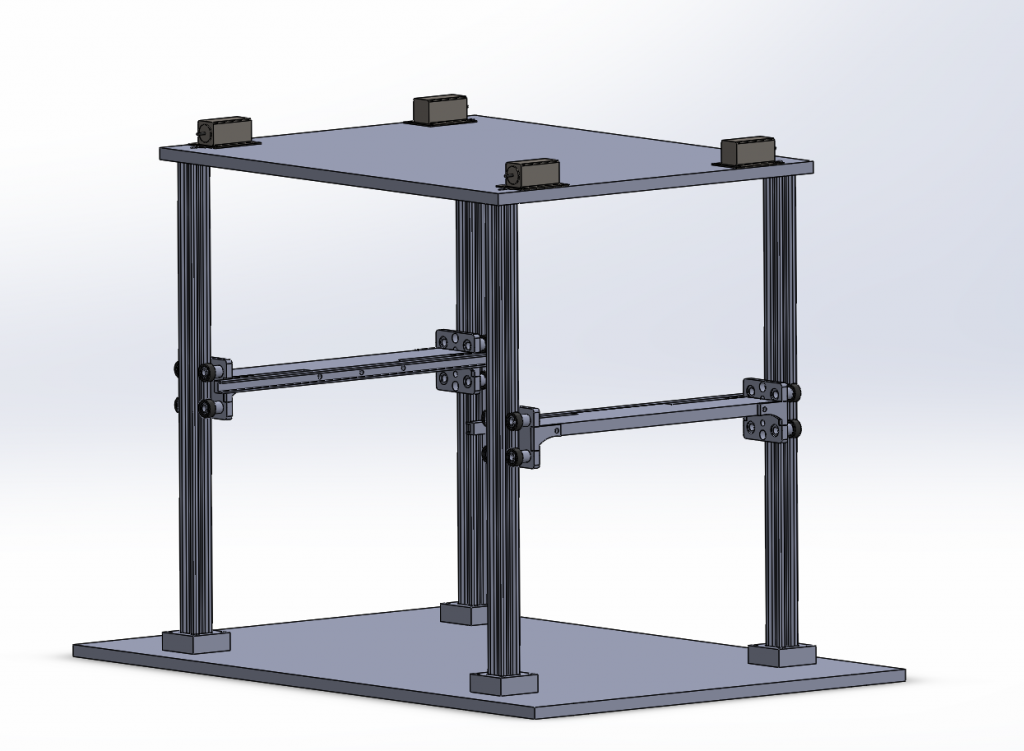

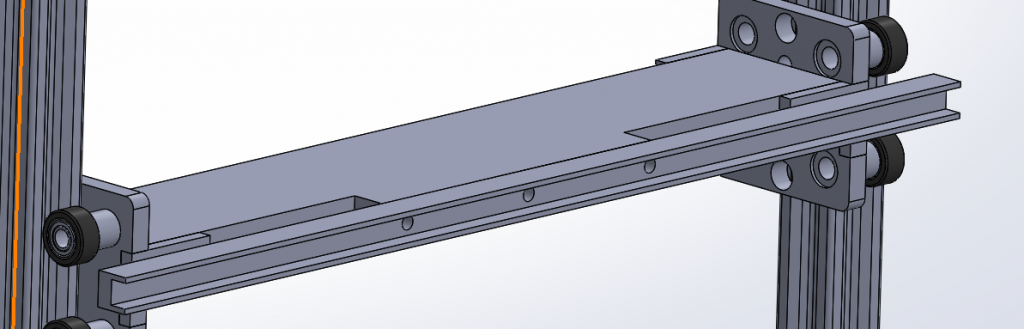

This week, I focused on resolving setbacks from my previous design and reconstructing the elevator system for the smart parking project. It was a challenging but rewarding process, as I worked through issues that had initially hindered the functionality of the elevator.

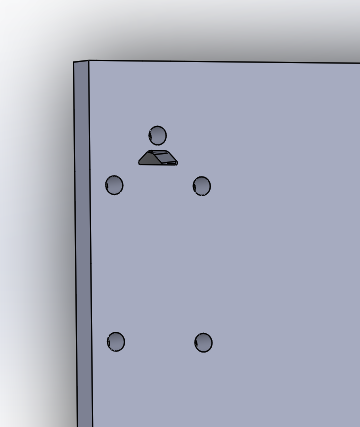

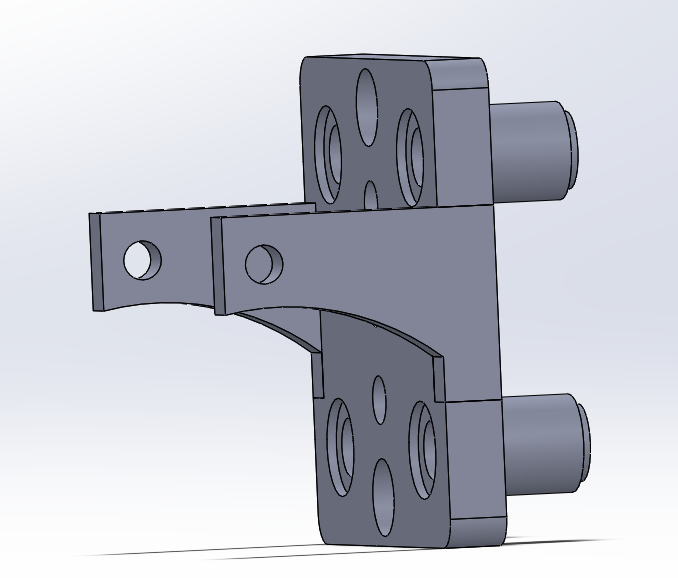

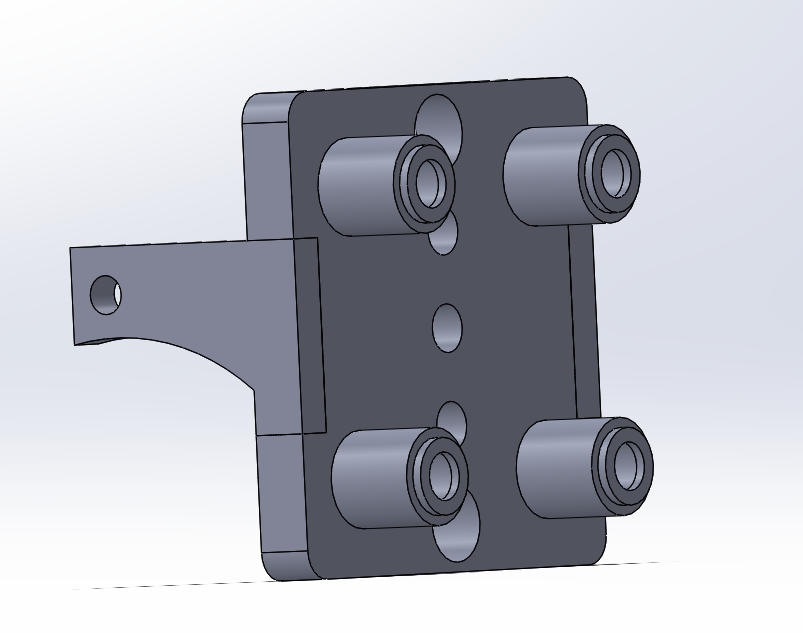

The first task was to redesign the V-Wheel plates, which connect to the aluminum beams. The dimensions from the previous design were slightly off, causing instability where the plates either didn’t fit securely or were too small. I carefully adjusted the measurements to ensure precise fit, preventing any risk of the parts slipping or becoming misaligned. In the same process, I decided to streamline the design by integrating the middle layer, which was previously a separate part, directly into the V-Wheel plate. This change simplified the overall structure and reduced the number of components, making the assembly more efficient. I also remade the arms on the plate for a stronger hold.

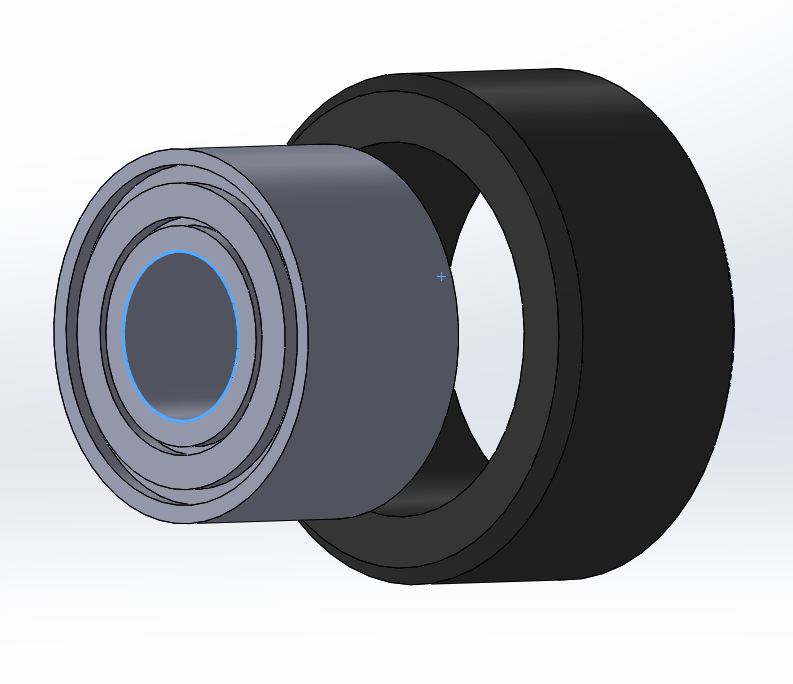

Another change related to the V-Wheel system. Initially, the wheels had two bearings to ensure smooth movement, but after further testing and analysis, I realized that this setup could be simplified. I opted to reduce the number of bearings from two to one, which not only made the system easier to assemble.

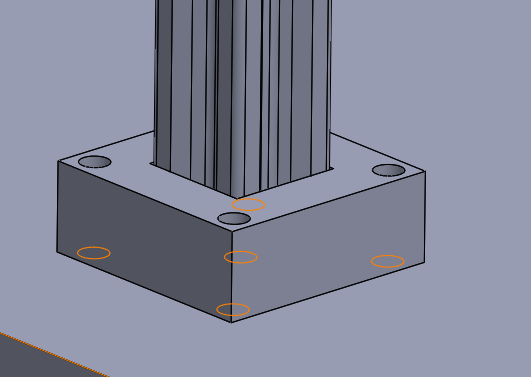

In addition, I revisited the way the beams are connected to the overall structure. The original design didn’t allow for a secure attachment between the beams and the floor, which could lead to instability during operation. To address this, I added legs to the beams, creating a stronger connection between the beams and the floor, improving both the structural integrity and ease of installation.

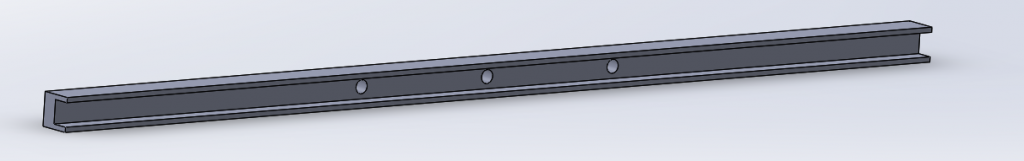

Another important revision was remaking the rail system, which will hold the ground plates carrying the cars. The rail system is essential for enabling horizontal movement, and the previous design lacked the precision needed for smooth operation. By redesigning the rails, I ensured that the ground plates would move seamlessly in the horizontal direction, providing more accurate and efficient car placement within the system.

Lastly, I designed a roof for the elevator, which serves as the mounting point for the stepper motors and the threaded rods that will lift and lower the elevator. By creating placement for the motors and threads, the entire system will function more reliably.