Mid-term presentation week

On this week we all stoped our work to work on the mid-term oral presentation together. So we all meet on monday to start discussing what we had to do, when and how are we going to do it. We divided one slide per person and each one managed to work on his/her slide during the week. In conclusion was a very good thing this presentation to see where we at and organize ourselfs better to make the progress that we want in the future, to be able to have our robot on time.

Individual work:

Adam:

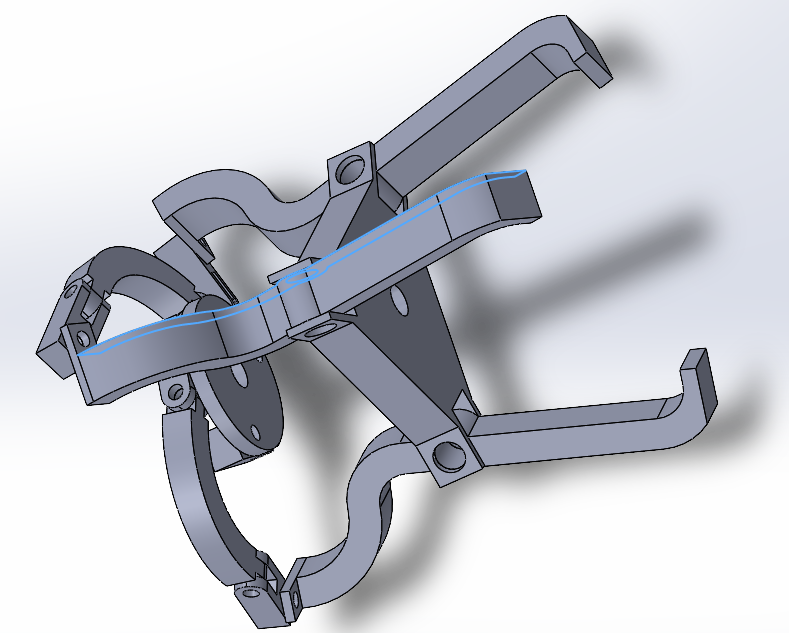

My part this week was reviewing the A, B and C requirements, because most of the initial requirements were too much over our heads and we needed to rethink and lower our exceptions. Also I have completed the assembly of the jaws so that we are able to show our first design of the jaws.

Adrian:

For the oral presentation, I looked into the problem domain, researching humanity’s continuous strides in automation and the benefits of our system in a real life scenario. Even though Norway and other scandinavian countries already have a system of sorting bottles and cans, our system will be most beneficial to countries that don’t put focus on recycling, specifically on bottles. Automating more menial tasks makes it possible allocate human resources to elsewhere, where human senses are of better use. Not to mention the environmental impact of more countries and states implementing a recycling system.

Jacob:

I did the entry slide for our presentation, as well as did a general managment of the whole presentation – decided who did what part and how it looks.

Farah:

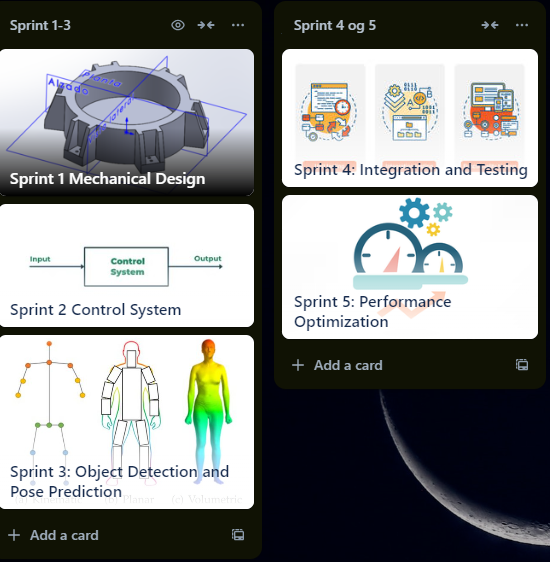

My part of the presentation was to talk about the project structure, methodology, tools, languages we used and our group meetings and communications platforms I wrote about how we implemented an agile approach and used the Scrum framework to break down our work into five sprints, each focusing on a specific part of the project. These sprints are planned to match the different phases of the project’s development, Currently, we are finishing up Sprint 1, which has focused on the mechanical design of our robotic arm

Sergi:

I did the last slide (Lesson learned so far and biggest expected challenges).

In my case we discussed in common the lesson learned so far and we arrived at this conclusion:

- Project Managment habilities (task distribution, problem-solving, time managment)

- SolidWorks modeling

- Use of ROS and different programming methods (point-to-point and machine learning)

For the biggest expected challenges we thought on:

- Material detection (by laser technology)

- Real-Time Monitoring System: Bluetooth system to control the robotic arm movement from a different location and remotely through and app or a web interface.

- Assembly and simulations

This was a good week to see where we are, our goals for this project and do a pause to think what are things that we have to focus more.

Pamela:

I was in charge of “Results so far”