Individual work:

Adam:

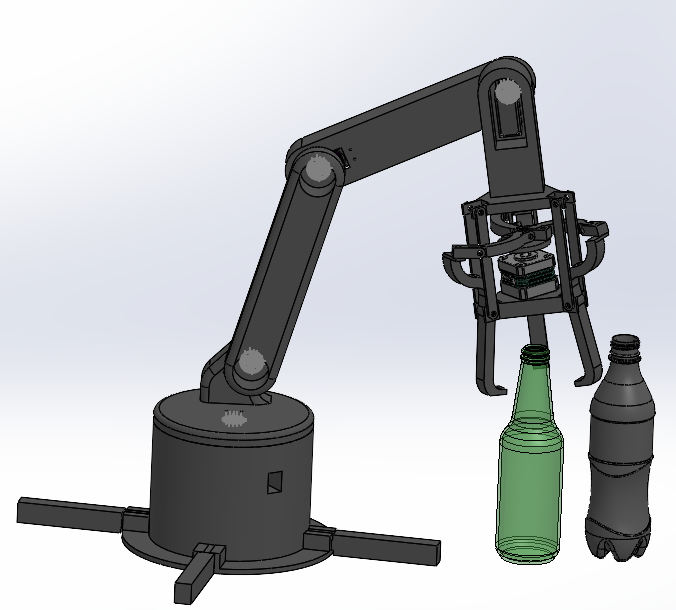

After changing few parts of the arm, I have sent Richard all the parts to be 3D printed and now we are waiting fot he parts to arrive.

Adrian:

Now that the 3D model is finished, this week I’m focusing on finalizing the URDF file. With the time I’ve had educating myself on ROS and MoveIt, it shouldn’t be too difficult, especially with little help from ChatGPT. It’s comprehensive, but easy to understand. And hopefully, when the model gets 3D printed and we’ve installed the motors, we’ll use Arduino and make test programs on the arm.

Jacob:

I helped redefine the whole arm and claw interface as the first prototype was a bit big and clunky. I also caught up on all of my missed blogs. And I helped Adam assemble and send the arm for 3D printing.

Farah:

Over the past few weeks, I’ve made a lot of progress on the project by setting up future sprints and pushing forward with the Unity simulation. Initially, I worked on breaking down tasks for our upcoming sprints, making sure we have a solid development plan in place. At the same time, I started integrating ROS2 into Unity, focusing on handling sensor data and getting the robotic arm to move. This really set the foundation for our future simulations

Pamela:

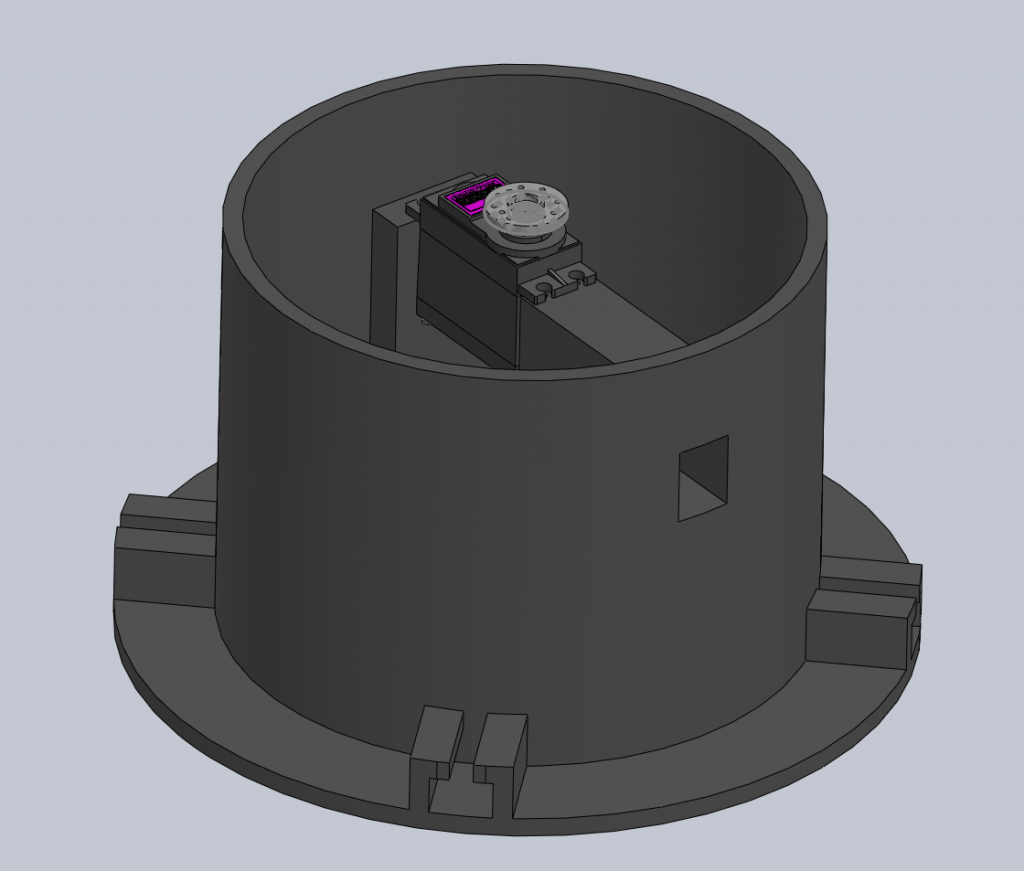

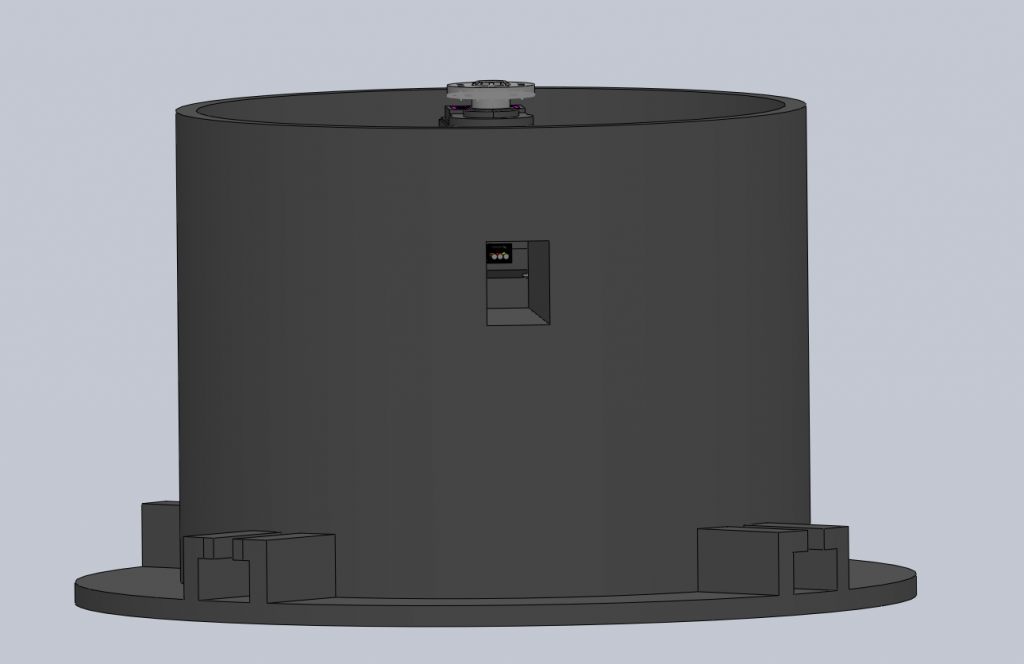

I assembled all the robot, here you can see some photos of the final result:

Sergi:

I looked for the best material for our robot, since we are going to 3D print our robot to make sure that it is a good material for our project and can resist all our movments and weight. I compared it with wood to see which material has better properties:

| WOOD | PLA | |

| Density (g/cm^3) | 1.5 | 1.24 |

| Young Modulus (GPa) | 12 | 4 |

| Fracture Toughness | low | higher |

| Strength (MPa) | 30-60 | 50 |

Wood density: Wood – Strength, Density, Hardness | Britannica

Pla density: datasheet-pla-filament-uk.pdf

Young modulus wood: What is Young’s modulus for wood? – Quora

Young modulus pla: Comparative Failure Analysis of PLA, PLA/GNP and PLA/CNT-COOH Biodegradable Nanocomposites thin Films

Fracture toughness wood vs pla: Pros and Cons of Using Wood Filament in 3D Printers – Revolutionized

Wood strength: 02-08-01 1..9

PLA strength: How Strong Is 3D Printed Plastic: A Comprehensive Guide

Once I did all this research, we can see that 3D printing with PLA has a lot of benefits such as less density (lighter material) with higher fracture toughness and more strength as well. That is ideal for our robot, so we confirm that PLA is the best material solution that it is in our hands.

I also thought of a more efficient way to place the wire of the servomotor that goes inside the base, so I redisigned our final base and this is the result: