23.09.2024 – 29.09.2024

“A dream doesn’t become reality through magic; it takes sweat, determination and hard work”

-Colin Powell

Group Summary

Dearly beloved,

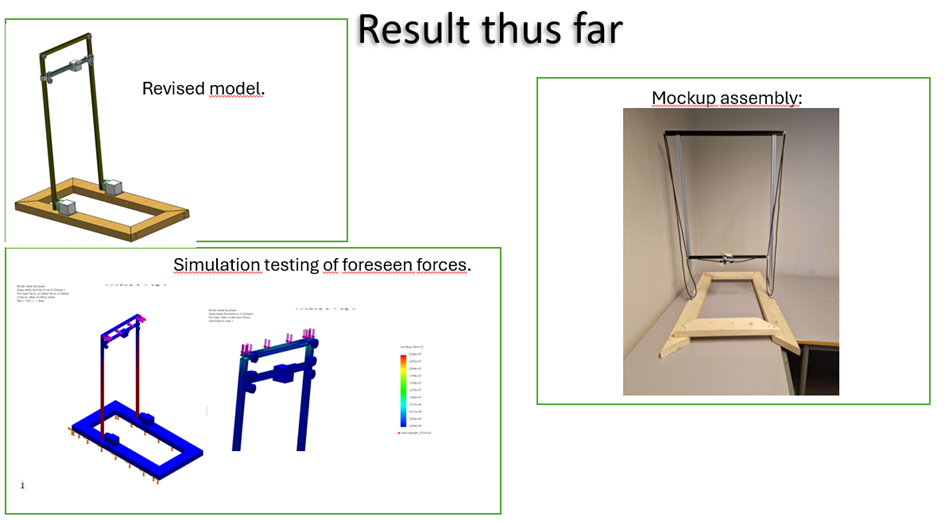

with the mid-term presentation coming up this week, it has been our main focus during our meetings both on Monday and Tuesday. Given our experience presenting our project in systems engineering, a small mid-term presentation like this will be a breeze. This week also saw our first physical prototype of the project, which you can see pictures of in Hans’ summary further down. Though not quite as technically up to date like the endgame we are aiming for, a physical model will always make it easier to observe and find potential issues early.

Individual Summaries

Eirik (Data):

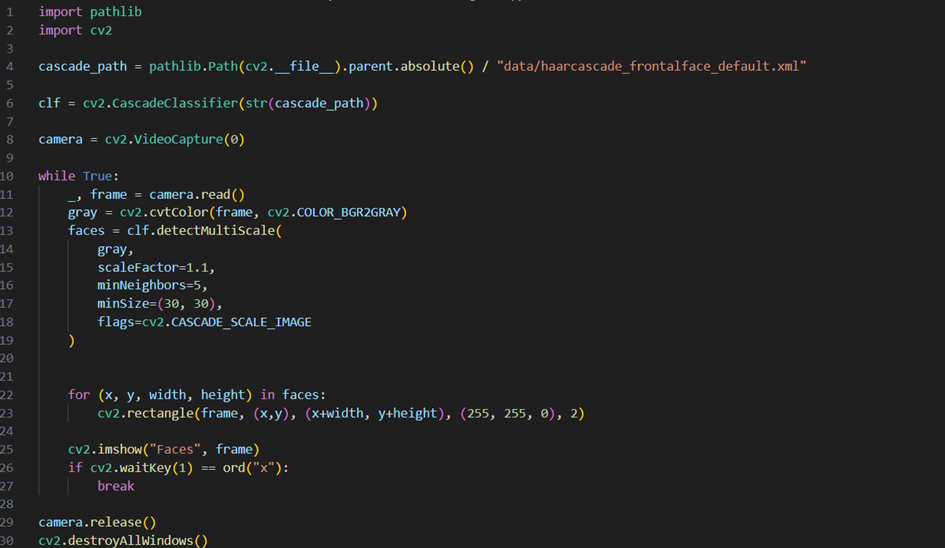

To everyone’s disbelief I have been doing some more computer vision programming in Python, again. I forgot to mention in the last blogpost that I ended up ditching the original computer vision course I was following, since it went more into detail on how computer vision actually works with matrixes and stuff. That is not really relevant for this project, I just need to know how to program it. Learning the entire foundation on computer vision can I save for another time. Instead, I found another course that uses the library for computer vision in Python, making it a million times easier:

After learning about code that will only display movements, either from a video or live camera feed, I went on to learn about facial recognition.

This is the same code that was used in the tutorials I watched, which simply will mark what it recognizes as a face with a rectangle. The code is capable of recognize faces from quite a long distance, but it also needs to be calibrated since it often can mistake random things in the room for faces. Now that I know how to code facial and movements recognition, I would like both elements into a single program.

Robin (Data):

This week have been less simulations than previous and focused more on making sure our product will uphold the goals we have set. One major difference in the system is to abandon the physical shooting of bullets to some sort of Infrared system.

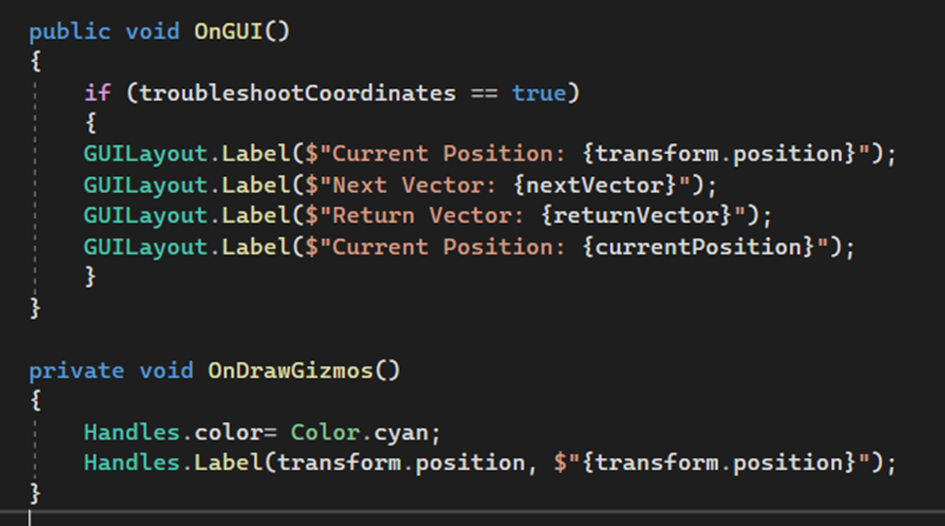

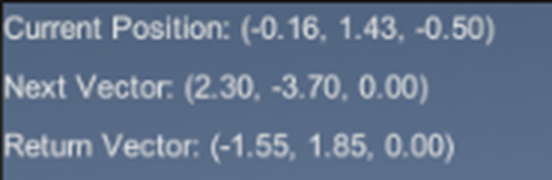

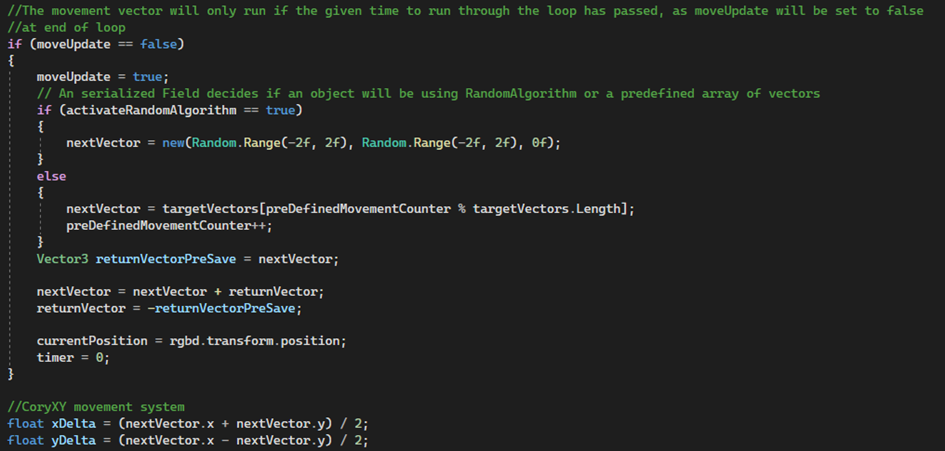

Thanks to some help from a friend, I finally managed to make the random algorithm to work, I learned a few tricks that were especially useful for debugging.

With this done, I’ve created a pattern of movement that can be a useful tool to create a more refined play experience. I can now choose which mode to run for each target and if we want, we can manually steer it through another movement system created earlier, giving the option of creating a 2-player experience.

In the video below you can see two targets where the closest target is moving using a prefabricated pattern and the target behind is using an algorithm that creates random vectors.

At this point, my focus should move away from simulations and onto other parts of the system so that we can create our first prototype and prepare for a physical solution.

Fredrik (Data):

This week was a less productive week from me due to an exam on Monday 30th, but I did make a point counting system that I wanted to work like a background system, but faced the problem that I could not manage to find a way to make the scripts run simultaneously. (bilde av kode kommer)

Vetle (Electrical):

I have been continuing my work on stepper motor drivers. I am making the footprints and symbols for the different components that we will use, while also figuring out which components to use. We have decided to move away from physical projectiles and rather go for an optical system. Making it optical will make it easier to make a detection system, but it also presents some challenges. It will be similar to laser tag, so we would use infrared. I have tested the motors and the stepper drivers which you can see in the video below.

Kadir (Mechanical):

This week, Hans and I built and installed some parts of the project. I then took over by refining the design and ensuring precise measurements for proper alignment of the components. I also began designing a section of the laser gun, which will have the ability to rotate in a half-horizontal and half-vertical arc. The horizontal movement will be achieved using an internal gear mounted on the head of a shaft, which is connected to another gear driven by a small motor. For the vertical movement, an additional gear will be used to rotate the gun in a half-vertical arc for added flexibility. The measurements used include, for example, a shaft diameter of 3 mm and a horizontal shaft length of 3 mm, with a rotation angle of 180 degrees for both the horizontal and vertical axes. Additionally, A5-watt motor will be used to ensure efficient movement. The laser gun will be mounted on an adjustable base to provide extra flexibility in aiming, and sensors will be integrated to improve accuracy

Hans (Mechanical):

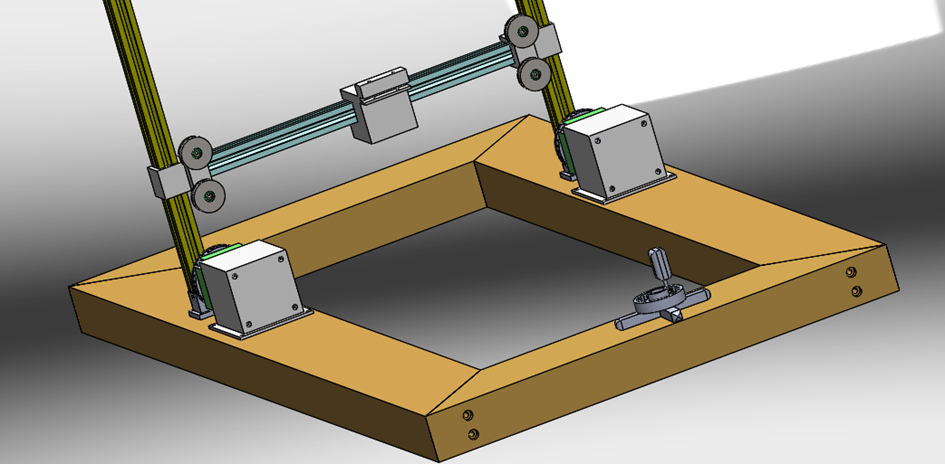

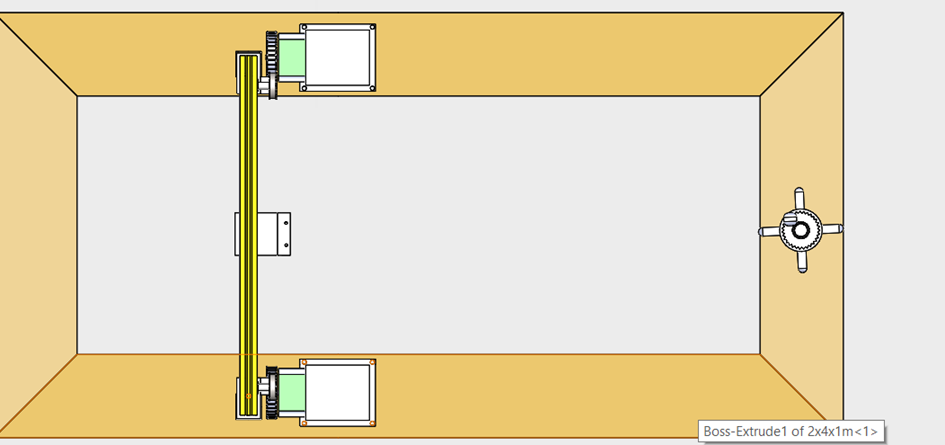

This week, I focused on constructing the fundamental framework of the project, starting with assembling the main components and laying the groundwork. After that, I 3D-printed some parts to test the horizontal and vertical movements. I then matched these parts in SolidWorks and performed a detailed simulation to evaluate the performance and identify any weak points in the design. Based on the simulation results, I developed a plan to adjust the parts that needed strengthening or modification and applied those changes directly to the design.

After implementing these adjustments, the movement of the components improved significantly, enhancing the overall efficiency of the project. Finally, I collaborated with Kadir to finalize the measurements for the laser gun design. We reviewed the dimensions and the final measurements to ensure a precise balance between movement and accuracy. Additionally, we introduced further improvements to increase the system’s stability, including optimizing the connection mechanism between the axes for smoother operation.