Machine:

The last few posts have been scarce on updates from the machine students. We have however been making good progress on the tank.

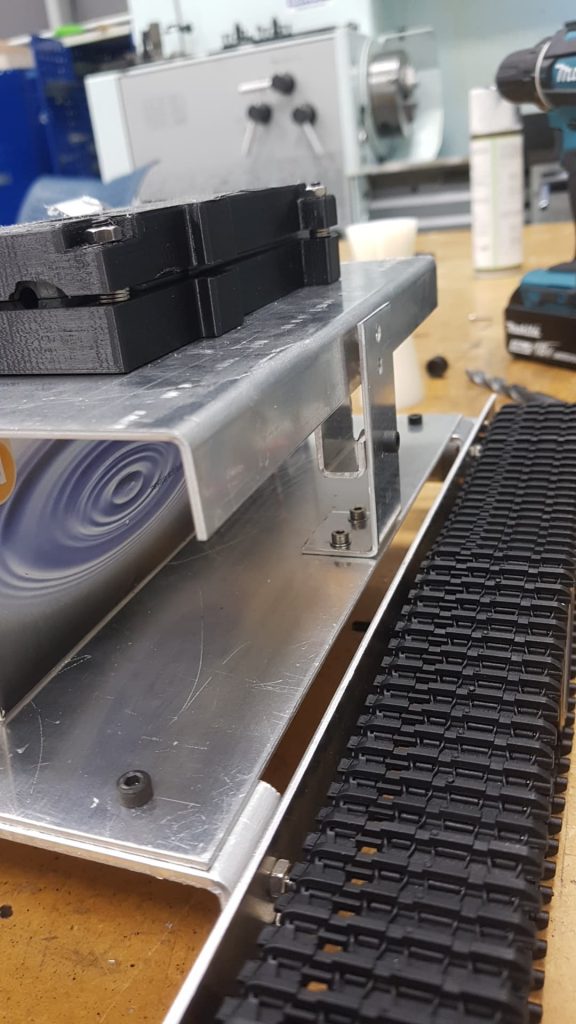

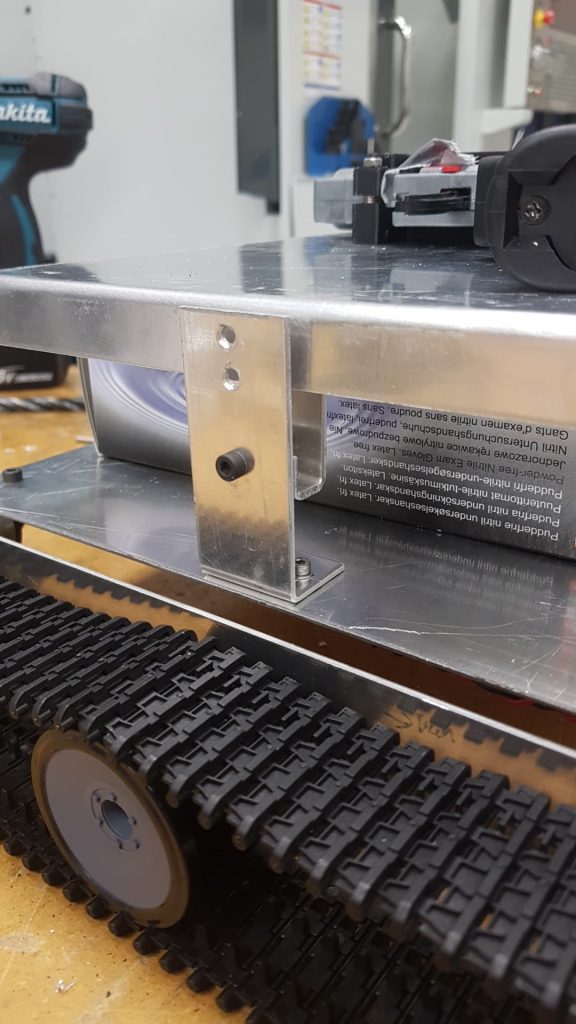

By simple laying the gun on a flat surface we could tell the gun was not level. This would affect the accuracy. It also had limited points to which it could be mounted on the top surface of the tank. To solve these two problems we had the idea of a mold in which the gun could be placed. Even after carefully measuring the gun in order to replicate it to a 3D model, the finished 3D-printed mold did not fit the gun as intended. We heard rumors of long queue times for printing so instead of waiting and reprinting another version only to be presented with the same problem we decided to grind and cut down anything preventing a decent fit. The top part of gun has been raised 3 mm and several washers are placed between the top and lower half of the mold to avoid over-tightening the low-strength polymer.

We also created L-shaped brackets for the top plate. By manually bending and drilling holes we’ve ended up with some parts with inaccurate angles and dimensions compared to our Solidworks assembly. How the top plate is fixed to the bottom is critical for the tilt-function to work. To counterbalance the inaccuracy, we used smaller bolts in order to allow for small adjustments of the brackets. We also realized how it would be better for the bolts connecting the bracket and the top plate to have 2 points to rest on, so we included the J-shaped brackets. The gap at the top of the brackets would allow for some adjustment when attaching the gears responsible for tilting.