Meron:

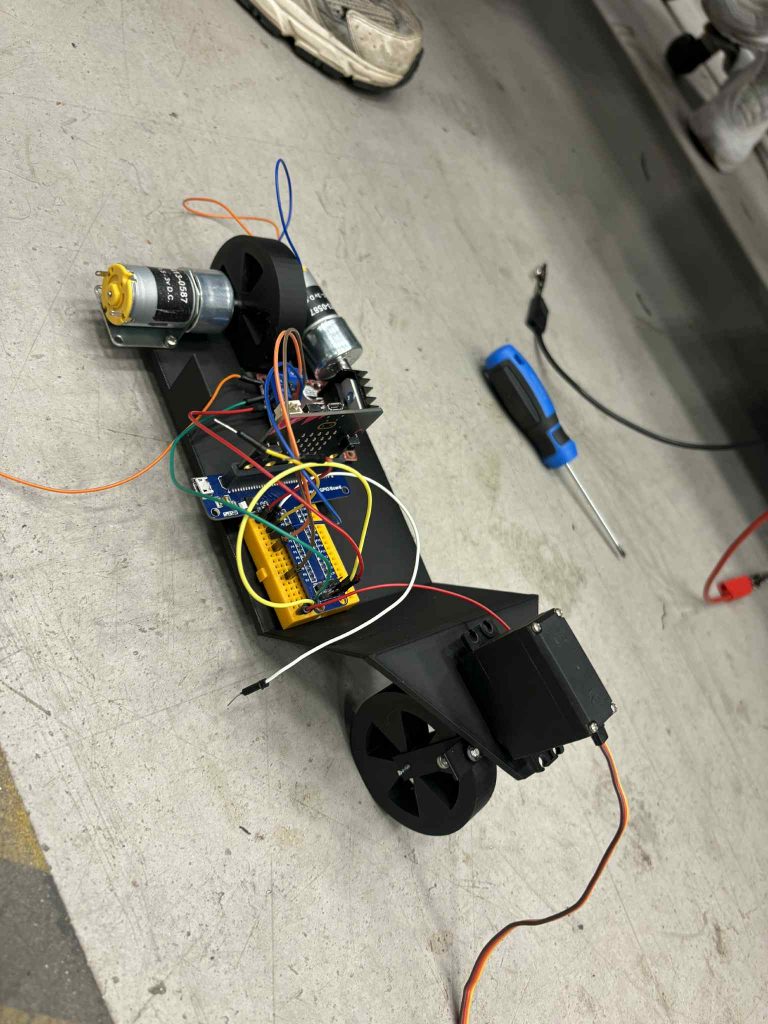

This week, I continued working on Phase 2 of our auto-balance motorcycle project, which focuses on the steering system. After finishing the design last week, I printed out the new parts and started assembling the motorcycle in the workshop.

The main goal was to test the steering mechanism in real life, and I’m happy to say that it worked successfully, as shown in the picture and video below. It was exciting to see the design I created in SolidWorks come to life and move and turns .

Our next plan will be to start designing and testing the balancing wheel system for the motorcycle, which will help it stay stable and upright while moving.

Salim:

This week we did several things.

We assembled the new motorcycle for phase 2, including the controller and the servo control.

In this video, I will focus on the controller and how it operates with the servo.

As you can see, there were some problems.

First of all, the delay was bigger than expected. This may be because we are using radio on makecode, and the signal quality is not optimal.

It could also be caused by having many else-if statements in the code.

Another problem I discovered is that the speed cannot be adjusted on the controller. This is because the pins are not analog.

I can look into this later, so that we can control the speed of the motorcycle correctly.

The controller’s R button (P16), fell off. So I had some issues there. We tried to go to Henning, but he told us that it could be saved. Muhammed is going to try and save it.

We also did some measurements to calculate the balancing wheel.

This is the first step in building the balancing wheel.

We wanted to calculate the wheel accurately and even talked to Børge (our physics teacher) to guide us with this.

I understood that we need to do it through trial and error with different screws.

This will be done after the test wheels arrive.

Measurements:

- Rotation speed for 7V: 1400 RPM

- 4 large screws weight: 0.064 kg

- 10 small screws and 10 nuts weight: 0.066 kg

Next week, we will start programming the balancing wheel as well.

I will work closely with Muhammed, which is why we will set up a Git repository.

Muhammed Ø:

This week we focused on assembling the motorcycle to test and verify that the steering system is working as intended.

After integrating the new functionality, we noticed a increase in delay when sending commands from the controller. We suspect this is due to built in radio on the micro bit, potentially compounded by our code. Our plan is to treat this as a hardware related problem issue for now, which we will address by writing more efficient code later in the project. Since the self balancing system will be an independent module and will not interact with the controller, we are confident this latency will not affect its functionality.

During testing, we encountered a physical problem, one of the buttons on the controller broke off. Fortunately, after inspection, we confirmed that two of the pins of the button were still intact on the board and the last still being attached to the button itself as shown in the pictures below. By holding the button in place, we verified it still functions. The solution is straightforward, we will try to solder the button back in place.

We also delved deeper into the calculations for the self balancing algorithm, like Salim already has mentioned. In our research we made an interesting discovery regarding motor, by applying a voltage higher than the recommended rating(around 7 volts instead of the standard), we can significantly increase the motors rpm from around 600 to around 1400.

this extra power could be very useful for the quick adjustments required by the self balancing system. While sustained use at a higher voltage could potentially harm the motor, we believe that short, intermitted burst needed for balancing will not cause any issues.

We are looking forward to continuing our progress on the self balancing system next week