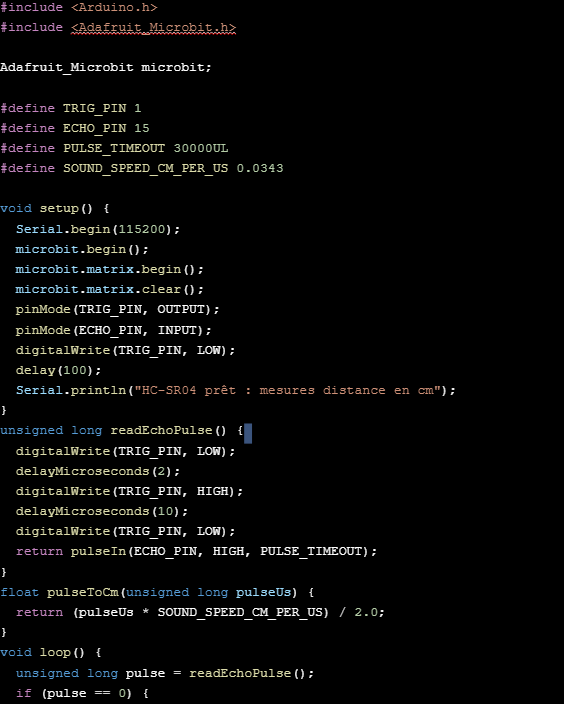

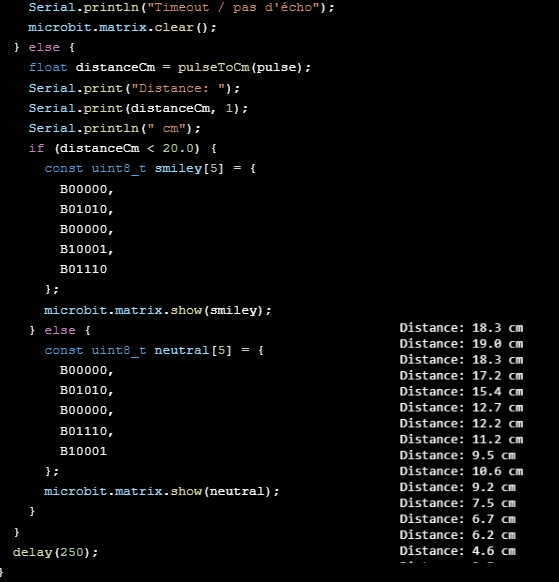

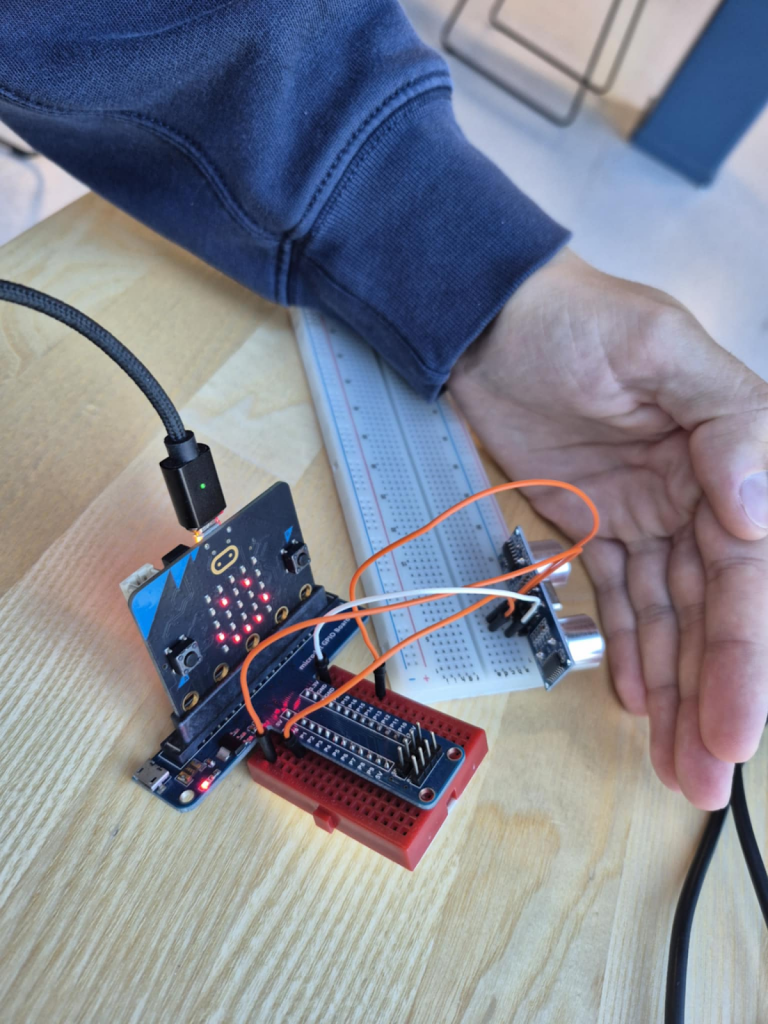

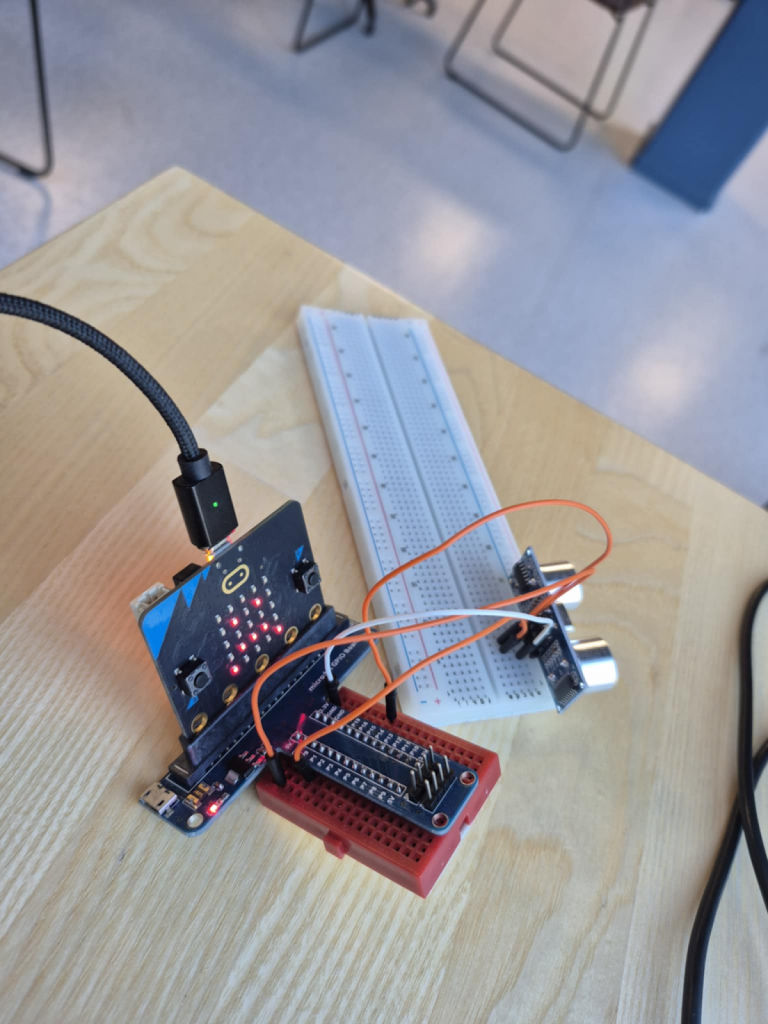

Théo:

This week I succeeded in having good feedback from the sensor with this and this basic assembly.

Next step will be to implement all four sensors around the car and instead of changing the smiley face, change the direction of the car.

Sondre:

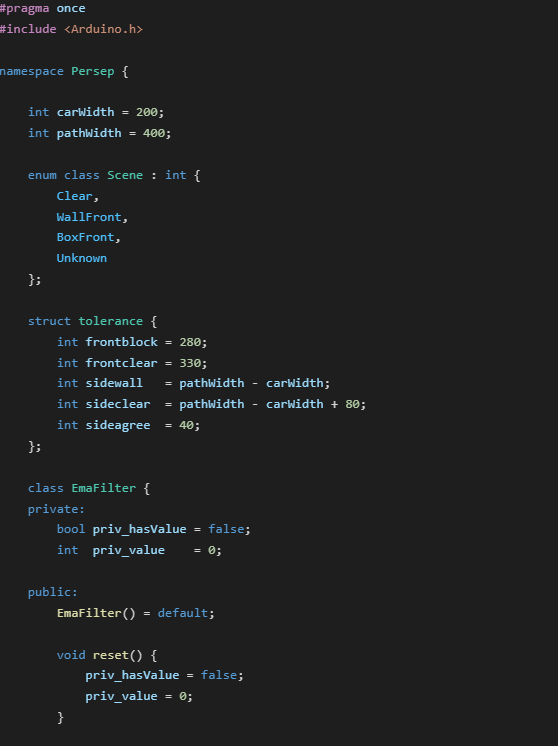

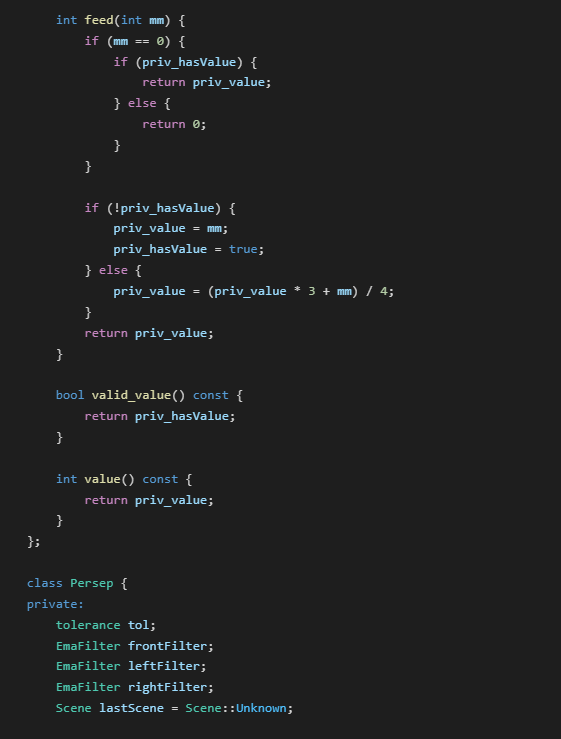

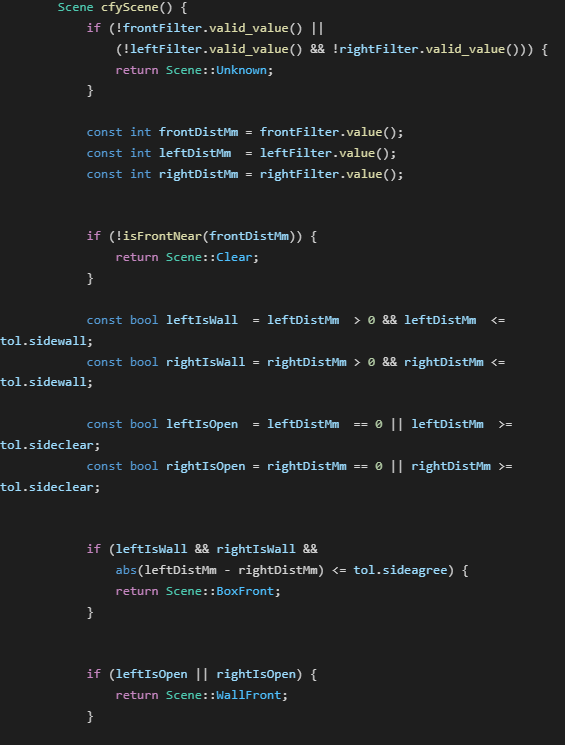

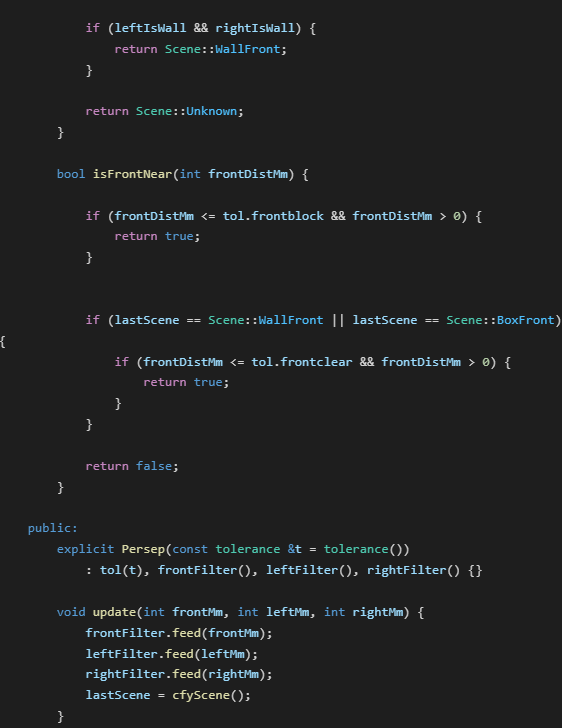

This week I focused on building a library for box detection using three ultrasonic sensors on the robot. The idea is to give the robot a simple way to decide whether it is facing a wall or a box.

The method works like this:

- First, I look at the front sensor. If the distance is above a certain threshold, the robot knows the path is clear. If it’s below the threshold, then something is in the way.

- After that, the side sensors come into play.

- If both sides report short distances and the difference between them is small, that means the robot is facing something symmetric like a box.

- If one side is blocked and the other side is open, that’s more typical of a wall, meaning it has hit a turn in the path.

- To make the detection more stable, I used two different thresholds: one to decide that the path is blocked, and another (slightly higher) to decide it’s clear again. This prevents the robot from switching back and forth too quickly when the measurements fluctuate.

I also added a simple filter so that sudden jumps in the sensor data are smoothed out. That way the detection becomes more reliable in practice.

Next step will be to test this logic on the course we are building, with both walls and boxes, and adjust the thresholds until the robot can tell the difference consistently. Theo has worked on the code for ultrasonic sensors. So we will need to integrate this with the logic so that it will receive real time data and not only demo numbers.

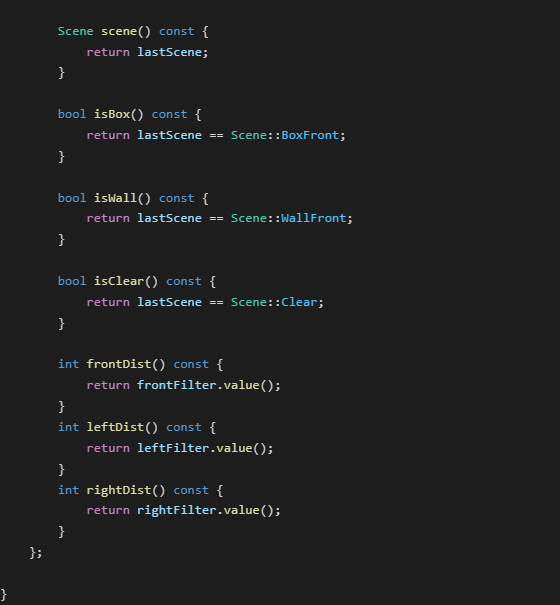

The code for the logic of box detection is pasted under:

Anette:

This week I have mostly been looking into the power system and how we will solve this. Our main issue is predicting the energy consumption of the components, especially for the motors. I have not been able to find the datasheets for the motors with the encoders, so we are using the information from an online retailer for now. The goal is then to make the power system with this in mind and we will test the motors at a later date when we get them. We have also been working a lot on the presentation.

Matias:

This week I started working on the PCB design. We decided to include two L298 motor driver modules to control the motors efficiently. I also added the flyback diodes to the circuit. These diodes are essential because they protect the components from the voltage spikes generated when the motors are turned off a common effect caused by the inductive nature of the coils.

This process helped me understand more about how to properly design motor driver circuits and the importance of adding protection elements to ensure the reliability of the system.