Jørn-Erik

I have been modifying the application a bit hoping for a better user interface and a picture just for a smoother look. I am trying to figure out how the second page is going. This is how the first page will look currently.

Milani:

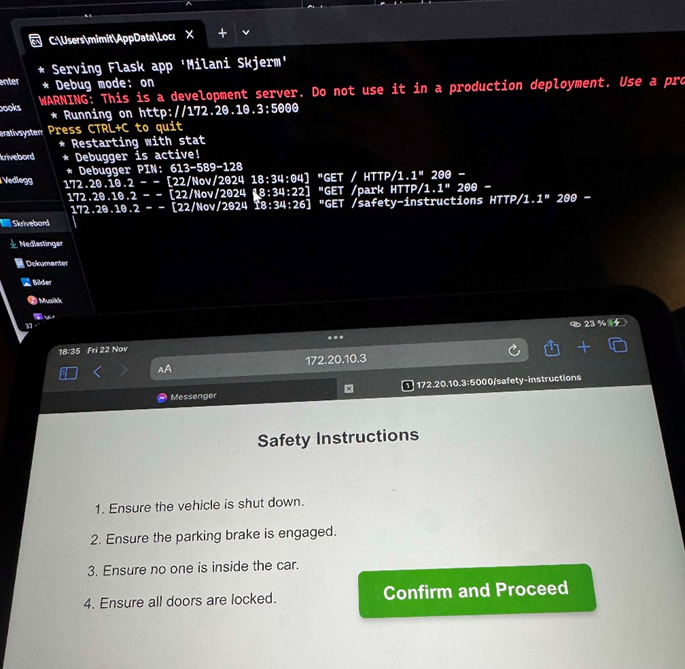

Performed further testing and improvements based on feedback and previous issues. Switched to a different network that provided access to the necessary resources to run the Flask project.

- Optimized Flask routes and fine-tuned transitions between screens.

- Ensured that receipt IDs were generated reliably.

- Conducted final checks on the safety instructions and wait mechanisms.

Azi:

GitHub Link: https://github.com/Azichi/Smart-Systems-Elevator-Project

Final Version with Vertical Movement Only

Overview:

For this week, we finished the elevator system by sticking to just vertical movement. The horizontal part wasn’t working, so we dropped it. I worked on the code, and Kim got responsibility for the hardware setup, testing and troubleshooting of the final system. Splitting it up like this made it easier to get things done. Most of this was taken from code I had already previously written, which made it much easier to set all of this up.

Final Setup:

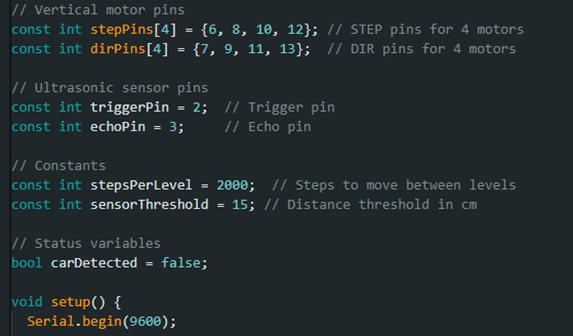

- What I Did:

- I wrote the code to control four motors, one for each beam, so the platform moves up and down smoothly and stays steady.

- I added a sensor to track where the platform is and make sure it stops in the right place.

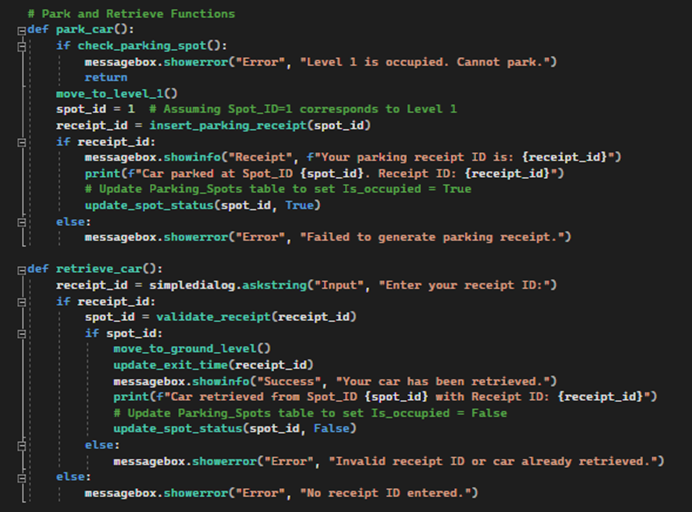

- Set up a database to handle parking and retrieval, so it updates automatically when cars come or go.

- Used Arduino to connect the code to the hardware, sending motor commands and getting feedback from the sensor.

- Used a simple interface where users can park and retrieve cars. It shows live updates on what’s happening.

How It Works:

- The four motors move the platform up and down and keep it steady.

- The sensor checks where the platform is and makes sure it stops at the right spot.

- The database keeps track of which spots are free or taken and updates when cars are parked or retrieved

- The interface lets users park and retrieve cars easily while showing live updates.

Final Outcome:

The system is now focused on vertical movement. It’s simple, works great, and ready to go.

Benjamin:

https://github.com/BenjiSerdar/Smart-systems-elevator-project.git

This week I finally set up the webpage on the domain I bought so we’re live. verticalsmartpark.xyz/VSP.html. I also spent the day deciding the different prices based of the already existing market.

My main contribution:

- Website development

- Backend development

- Finance

Kim:

Github link: https://github.com/Futumakii/VE3150-1-24H-Utvikling-av-smarte-systemer

My Contribution to the Elevator Project

This week, we completed the vertical movement part of our Smart Systems Elevator Project. While my teammate Azi focused on the coding, I worked on the hardware side of things. This division of tasks helped us stay organized and get the system running smoothly.

What I Did

Here’s what I was responsible for in this project:

- Connecting the Motors: I connected and tested the four motors to ensure they worked together to move the platform up and down smoothly.

- Setting Up the Sensors: I installed and tested the sensors that track the platform’s position and make sure it stops at the right level.

- Troubleshooting Hardware Issues: I worked on fixing problems with the motor belts, which were slipping during operation. However, we found out that we couldn’t fully fix this issue because we are missing some parts.

- Testing the System: Despite the belt issue, I tested the hardware to ensure it worked well with the code.

Challenges and Final Result

The motor belts slipped, stopping proper movement, and we couldn’t fix it fully due to missing parts. Still, the system works for vertical movement and shows the concept well. I focused on integrating the hardware with the code, and we’ve made solid progress.

Shanel:

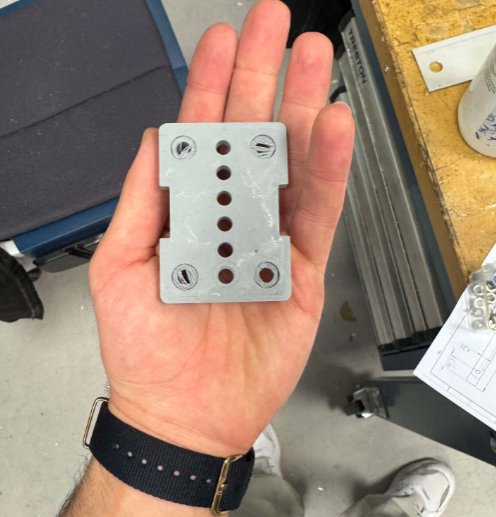

Finally, the week for testing the new system arrived, and it was a success. I assembled the belt with the new plates and belt holders and conducted a test of the vertical movement. The testing went smoothly and was successful.

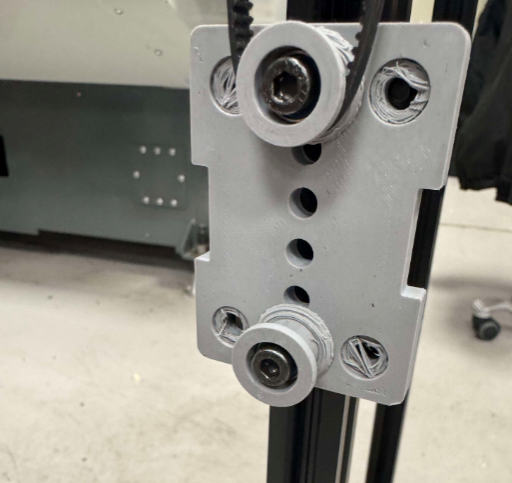

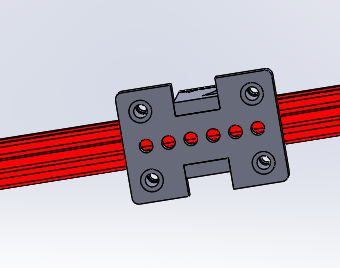

The new plates:

The new plate holders on top connected to the rem holders:

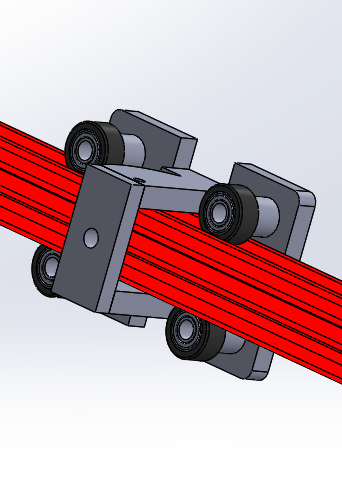

And the plates connected with the belt and belt holder:

All the parts fitted perfectly together and gave the opportunity to connect up the vertical movement.

This is a video of how the belt is connected up to the elevator side.

I attempted to record a video of the vertical movement, but since the beams weren’t stabilized with a roof, it turned out to be a bit tricky haha! Still I managed to achieve the result I was aiming for!

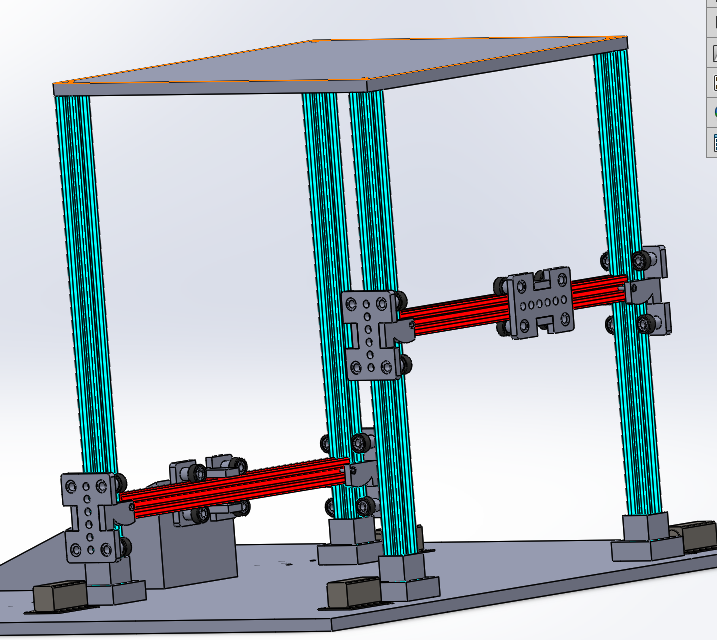

While setting up the vertical movement, I got an idea for enabling the elevator’s horizontal movement.

By redesigning the plates and adding a new beam, I finally figured out how to integrate horizontal movement into our system. This was achieved by connecting the vertical belt through the new mechanism, creating a seamless system for the plates.

meron

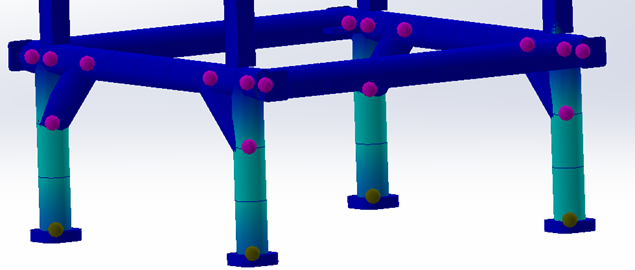

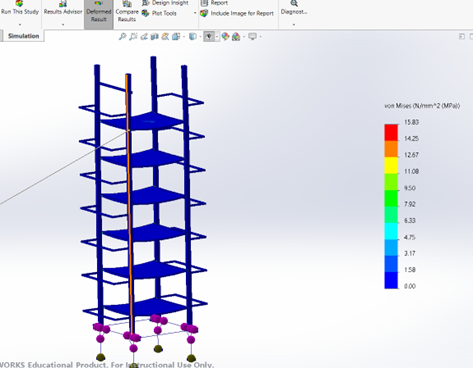

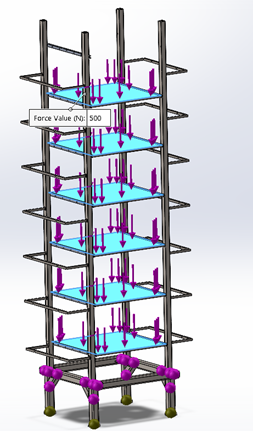

This week, I focused on two major aspects of the smart parking project: SolidWorks simulation and completing the elevator system in the workshop.

In SolidWorks, I explored simulation tools to analyze key factors such as weight, stress, and safety margins. Although I do not have produktutvikling 2 this semester, it was an excellent learning opportunity that proved invaluable for the project. These simulations provided crucial insights into the system’s structural integrity and performance under various conditions.

In parallel, I continued working in the workshop to finalize the assembly of the elevator system. This hands-on work involved refining the connections and ensuring that all components were properly aligned and functional. Completing this phase brings the project one step closer to full operational readiness.

This combination of design validation through simulation and practical assembly work has been instrumental in advancing the project, ensuring both reliability and efficiency in the final system.