Group:

As we put the system together physically we realized we did not have the thread and material needed for our system so we had to do an entire turn over and recreate coding and materials.

Shanel:

Because we didn’t have the necessary wire for the parts I printed, I had to remodel the system to work with a belt and pulley system.

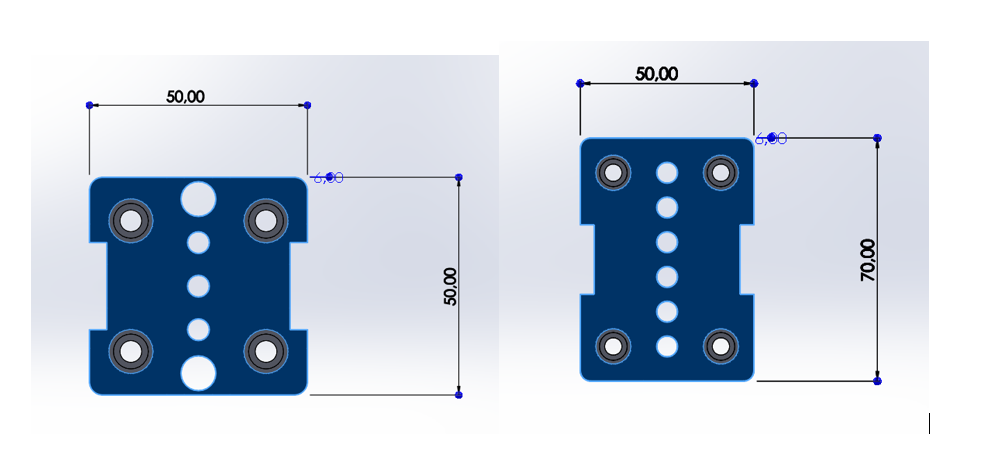

I started by redesigning the slide plates.

I had to increase their length to create space for the belt holders, as they needed to be connected to the plate.

The plates arm for to hold the ground holder got a new and stronger design too for to be able to hold up the weight and pressure that will be put on the plates.

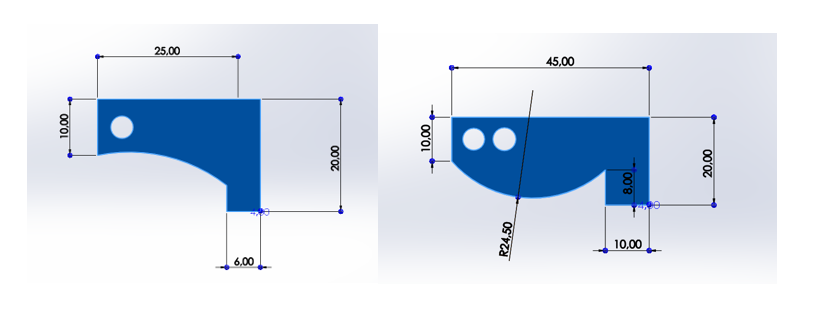

Ive also have had to change the design of the ground holder to adjust it to our real size protype.

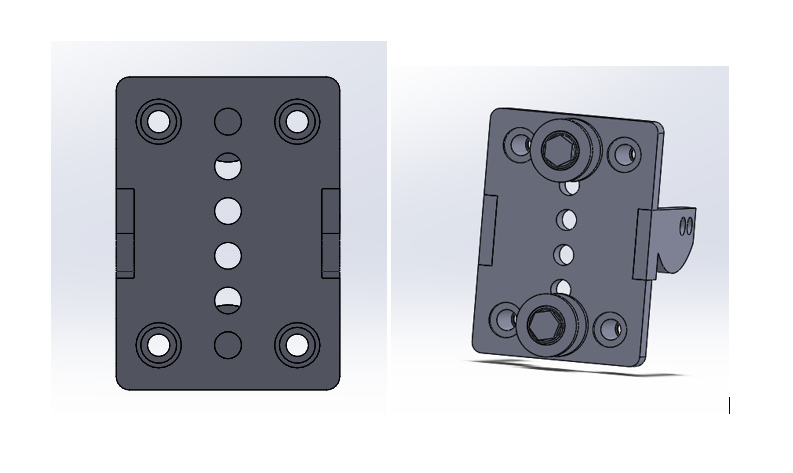

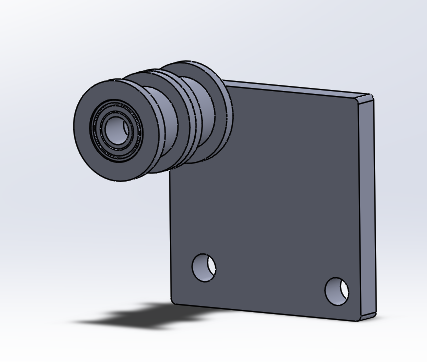

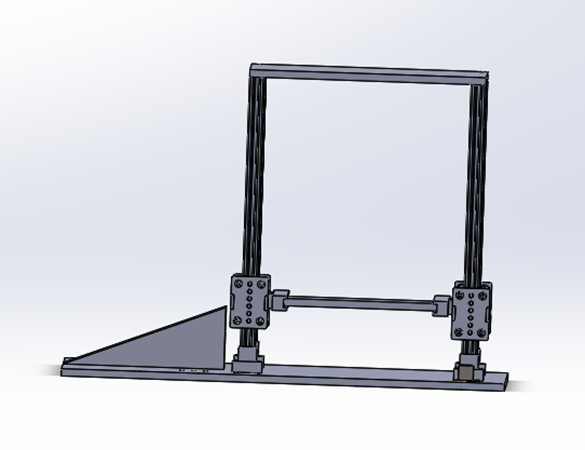

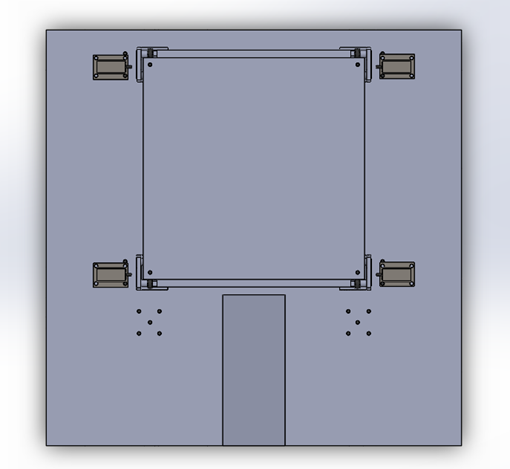

Due to the changes in the lifting system, I had to adapt the design to incorporate four motors, one to each beam for controlling the up-and-down movement. To ensure smooth operation and proper tensioning of the lifting belt, I added guide wheels on the lifting plate. These wheels help direct the belt over the appropriate paths, as illustrated in the pictures.

A wheel is positioned at the top of the plate to guide the first circulation of the belt, while a second wheel at the bottom manages the second circulation.

A final and entirely new additions to the system was a top plate for the beam, designed to hold the belt at its top position. This plate is connected to two belt holders, which guide the belt along its intended path.

And of course the belt holder which is also a new part.

With all these changes, the entire modeling process for the project has been transformed

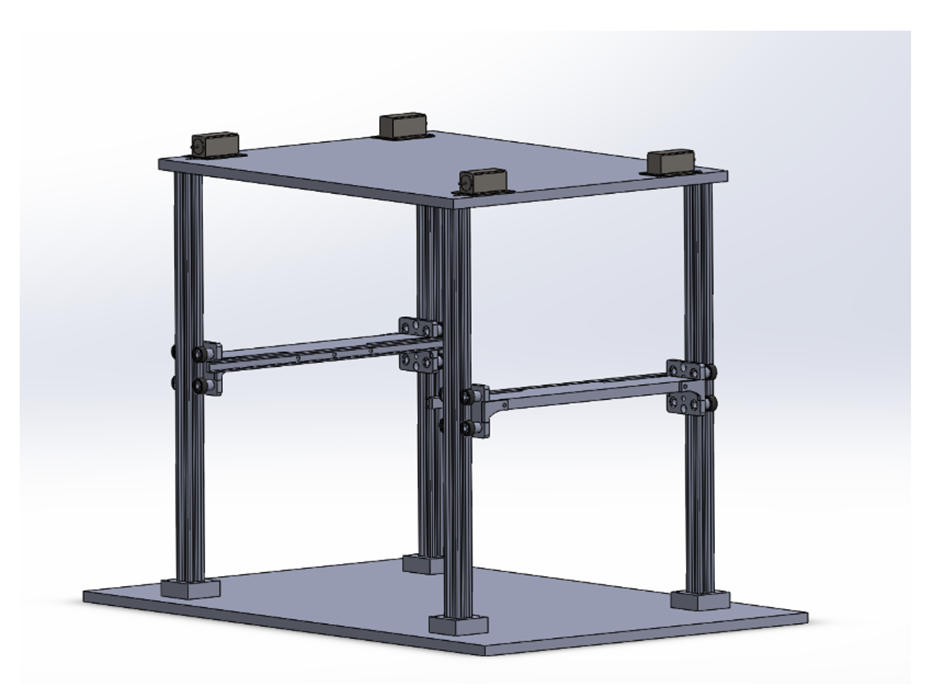

Before:

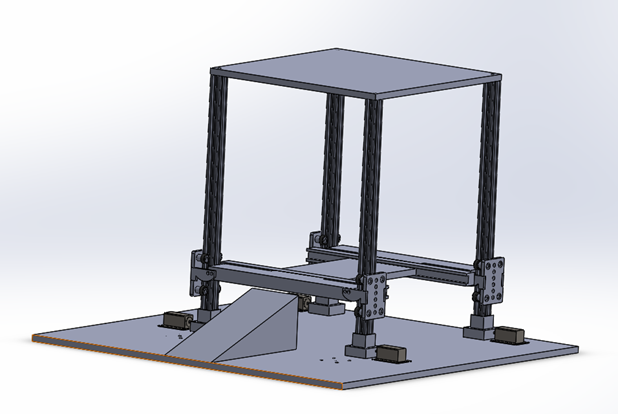

After:

As you can see, everything has been completely revised. The motor has been moved to the floor to ensure correct belt placement, the plate holders have been repositioned to the other side to support the belt, and a ramp has been added for improved functionality.

Its truly been a time eater to do all this changes but now we finally have a possibility

Milani:

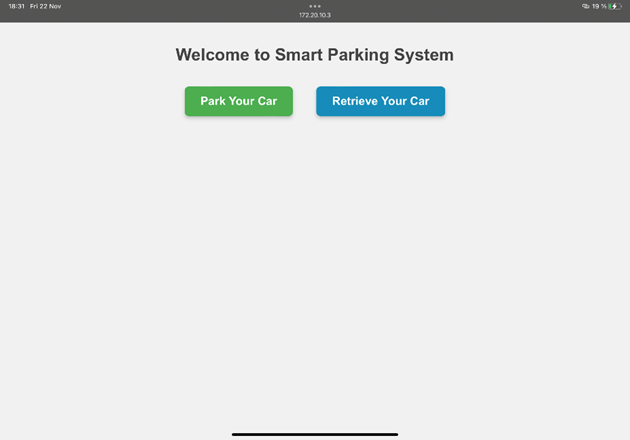

Continued developing the project and added several features, such as generating unique receipt IDs and implementing safety instructions before parking.

- Completed CSS styling for an improved touch experience.

- Implemented step-by-step safety instructions and automatic screen transitions.

- Began testing the project on the Flask server.

Challenges:

We initially tried running the project on the school network, but encountered issues because the network blocked access to essential ports and resources. This made it difficult to test the project effectively, and we had to find alternative solutions.

Azi:

Preparing for Testing

What I Did

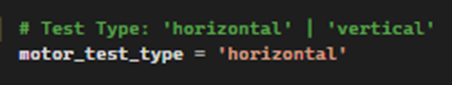

This week, I focused on creating a code to easily test the vertical and horizontal motors separately to make sure everything works as expected. The full system isn’t ready yet, so I kept things simple.

- For the vertical test, the code handles the platform moving up and down, just like it would during normal operation.

- For the horizontal test, I wrote the code to handle side-to-side movement.

How It All Works

- Picking the Test Type:

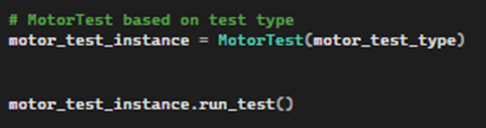

The code has a simple setup where you just choose whether you’re testing the vertical or horizontal motor. You do this by changing one variable, motor_test_type, at the top of the code.

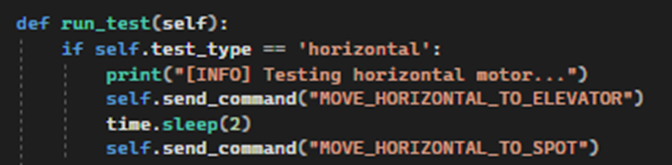

- Horizontal Test:

The horizontal motor’s code is shown below. The idea is to move the platform sideways between the elevator and parking spot.

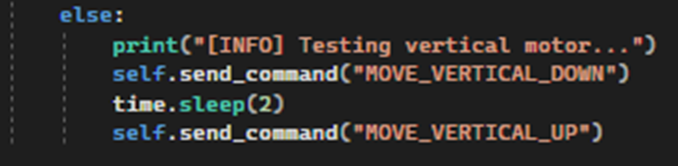

- Vertical Test:

For the vertical test, I programmed the motor to move the platform to different heights. No fancy feedback loops or sensors were involved, just simple movement to verify the logic.

How the Code Runs

At the end of the code, it runs the motor test based on the type you picked. Here’s how it looks:

Where We Stand

We now have a code that strips away all of the complicated elements and gets down to the basics of vertical and horizontal movement of the elevator. Splitting the tests like this makes it much easier to focus on each part individually, and now everything’s in a good place for integration.

Kim:

Supporting Motor Testing

This week, I supported Azi as he worked on writing the code for testing the vertical and horizontal motors for our tower parking system. While I didn’t handle the coding, I helped by sharing ideas on how to break down the tests into smaller steps. For example, we discussed testing each motor separately before trying to integrate them into the larger system.

I also gave input on how to adjust the motor speeds to ensure smooth movement and reduce wear on the hardware. My role was mainly about offering ideas to simplify the process and make sure everything was easy to troubleshoot.

Benjamin: This week has mostly gone into implementing the illustrational video. Originally the file type of the video was not what I wanted and the file converter I had found for this switch did not work. So I started researching other ways to implement the video. I found one way that almost worked perfectly. The video would show up on our webpage through youtube. And this honestly worked fine. But again, it wasn’t the best user experiance. when starting the video it would usually use a bit more time loading, and for me that wasn’t ideal. So I again started looking for converters, and in the end i found one that worked.

Meron ;

Workshop and Design Progress: Parking Building Prototype and Motor Solution

This week, I continued my work in the workshop, focusing on building a prototype of the parking structure. As seen in the picture, I used Weldment to weld rods with small plates on bottom. This approach allows me to adjust the size and placement where the components can be mounted to the main plate.

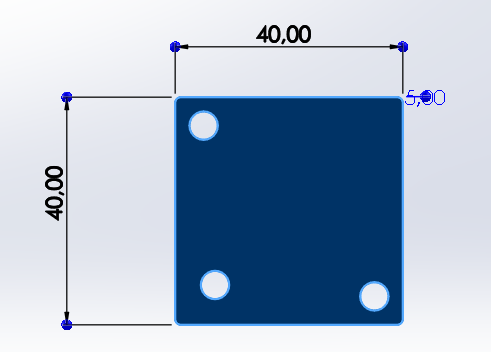

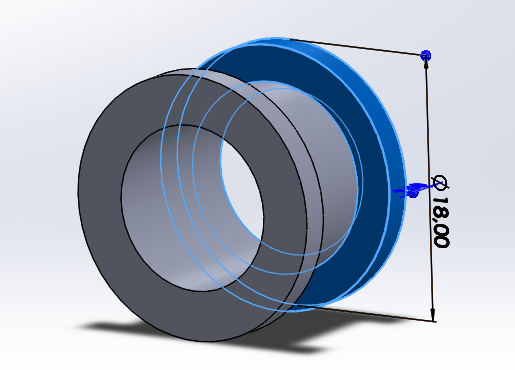

In addition to the physical assembly, we received advice from our teacher regarding motor selection. Unfortunately, the suggested motor was out of stock, so we had to work with the one motor we already had. However, this motor was unable to run the belt as required. To solve this, I came up with the idea of using a pulley system. I designed the pulley system in SolidWorks and then 3D printed it to integrate with the motor, allowing us to successfully drive the belt.This solution is a crucial step in ensuring the functionality of the system.